Your network is the backbone of your operation, but a single bad termination can bring it all down. As demand for 5G, AI, and IoT services skyrockets, the pressure for flawless, rapid deployment is intense. I've seen projects delayed and budgets blown by errors made during manual, on-site field termination. It’s a huge risk when your reputation is on the line. Pre-terminated fiber solutions offer a simple, powerful alternative: factory-perfected, plug-and-play cables that make installation faster and far more reliable.

Pre-terminated fiber solutions eliminate errors by moving the complex termination process to a controlled factory environment. This ensures every cable is tested for optimal performance, providing plug-and-play reliability that field terminations simply cannot match.

I remember a client in Brazil, Anson from AFC. His team was facing fierce competition where rivals were cutting corners, leading to network failures. The unpredictable quality of field splices was costing him bids. When we switched his projects to our pre-terminated solutions, the consistency and speed gave him the competitive edge he needed to win.

What Makes Pre-Terminated Solutions a Smarter Technical Choice?

It’s not just about speed. The real advantage lies in the engineering and quality control that happen long before the cable ever reaches your site. It’s about removing variables and guaranteeing performance from the start.

Their superiority comes from factory-controlled processes like precision polishing, rigorous testing for insertion loss (IL) and return loss (RL), and modular designs. This guarantees standardized performance and removes the guesswork from installations.

For an in-depth exploration of the benefits and technical standards, see this guide on pre-terminated fiber optic cables advantages.

Dive Deeper: The AIMIFIBER Advantage

At AIMIFIBER, we've built our reputation on this principle. Here’s a closer look at why a factory-terminated cable is technically superior to one terminated in the field.

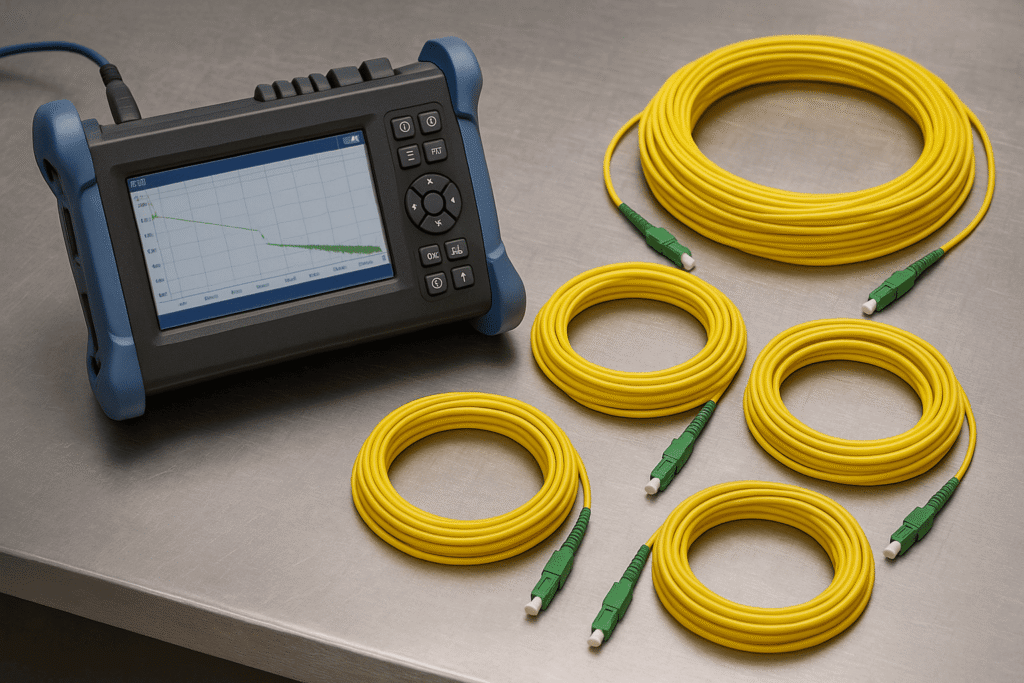

Factory Precision vs. Field Variables

In our factory, we use automated polishing machines and interferometers to ensure the geometry of every connector end-face is perfect. This is something that's nearly impossible to replicate in a dusty or cramped field environment. The result is a consistently low-loss connection, every time.

| Feature | Factory Termination (Pre-Terminated) | Field Termination |

|---|---|---|

| Environment | Clean, controlled, ISO-certified facility | Unpredictable (dust, humidity, temperature) |

| Tools | Automated, high-precision machinery | Handheld, portable tools |

| Testing | 100% tested (IL, RL, interferometry) | Spot-checked, often limited to power meter |

| Technician Skill | Standardized process, less skill-dependent | Highly dependent on individual technician skill |

| Consistency | Extremely high | Varies significantly |

Architected for Growth

Pre-terminated solutions are inherently modular. Systems built with MPO/MTP connectors, for example, allow you to scale from 10G to 400G or 800G just by changing cassettes and patch cords. This "plug-and-play" architecture means your network is ready for the future without needing a complete overhaul. It's the kind of forward-thinking design I always recommend to clients like Bayan in the US, who manages complex data center projects and needs a clear path for expansion.

If you're interested in how these solutions enable data center scalability and future-readiness, explore our resource on fiber optic cables for data center cabling infrastructure.

What Are the Key Design and Deployment Challenges?

Adopting any new solution requires careful planning. While pre-terminated systems solve many problems, being aware of the trade-offs is key to a smooth project and maximizing your return on investment.

The main challenges are the need for precise upfront measurements and managing inventory. While the initial cost can seem higher, these are balanced by massive long-term savings on labor, rework, and operational expenses (OPEX).

For practical advice on measuring, ordering, and managing installation, check out our expert insights on how you can ensure a successful fiber optic cable installation.

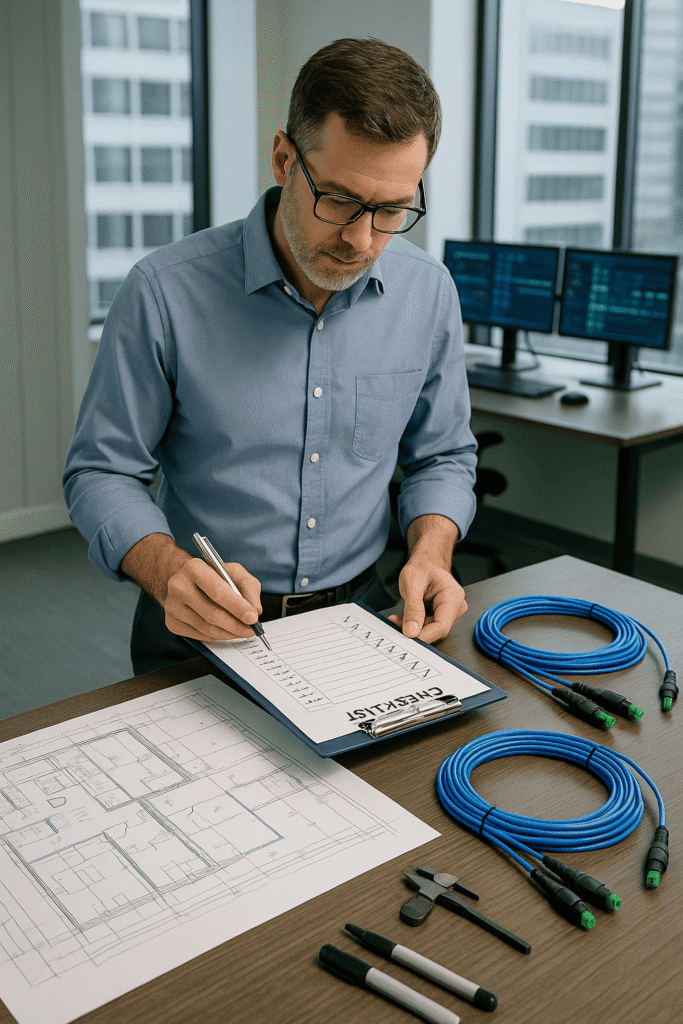

Dive Deeper: Planning for Success

Proper planning is everything. A mistake in measuring can be costly, as pre-terminated cables can't be easily shortened or extended.

Balancing Customization and Cost

The biggest hurdle is getting the lengths right. You need precise measurements from point to point. This requires more design work upfront compared to buying spools of cable. However, this initial effort pays off massively. Think about it: you eliminate wasted cable, reduce installation time, and avoid the need for highly skilled (and expensive) field technicians. For project managers like Fernando in Spain, whose annual tenders for Telefonica depend on flawless execution, this trade-off is a clear winner.

A Project Manager’s Checklist for Ordering Pre-Terminated Cables

Before you place an order, make sure you have answers to these questions:

- What are the exact point-to-point lengths needed? (Always add a small service loop!)

- What connector types are required at each end? (e.g., LC, SC, MPO)

- What is the fiber type? (e.g., OM4, OS2)

- What is the cable breakout configuration? (e.g., MPO-to-LC fanout)

- What are the pulling grip requirements? (Do you need a pulling eye to protect connectors during installation?)

Final thoughts

Pre-terminated fiber is the clear choice for building modern networks. It reduces errors, dramatically speeds up deployment, and guarantees the performance needed for tomorrow's technologies.