FTTH Drop Cable Maintenance & Troubleshooting Techniques

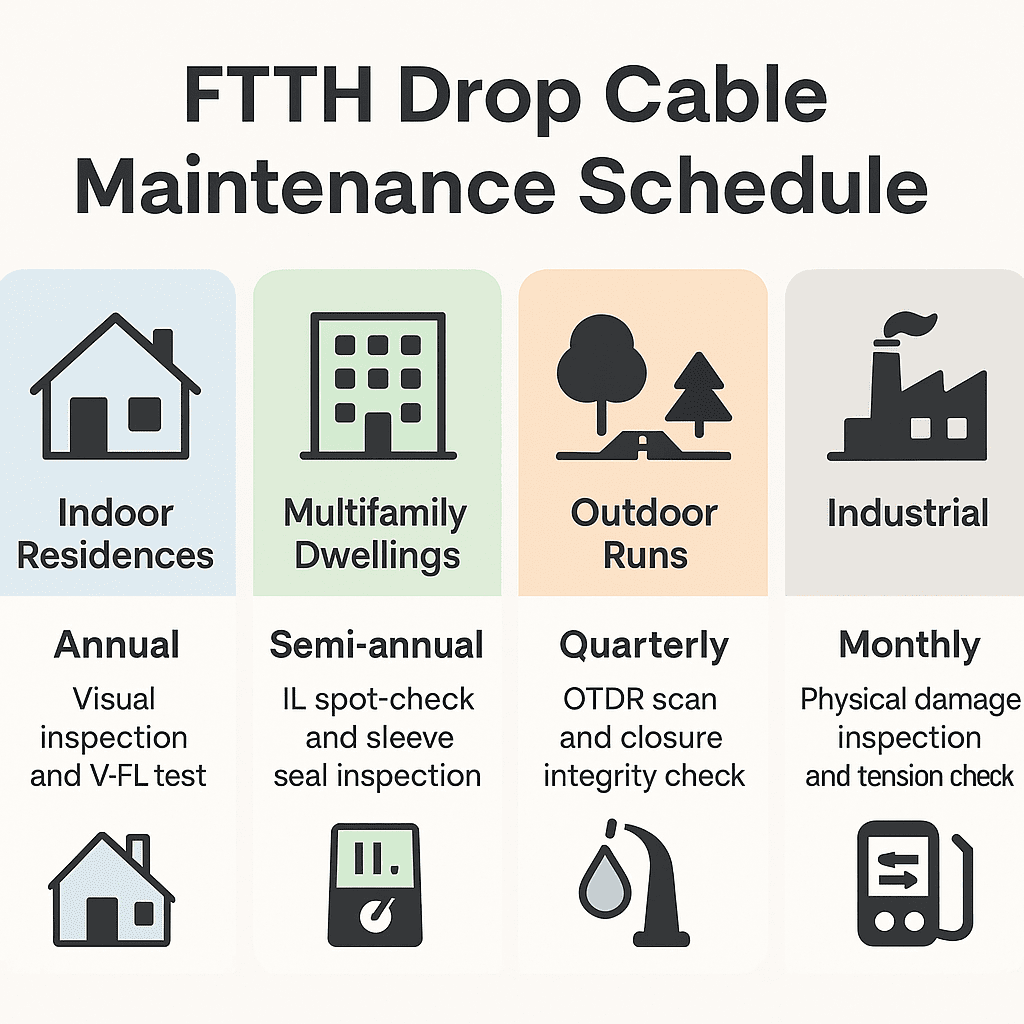

A clean vector layout divided into four panels—Indoor Residences, Multifamily Dwellings, Outdoor Runs, and Industrial Sites—each with a simple icon. Beneath each icon are the recommended check intervals (“Annual: Visual inspection & V-FL test,” “Semi-annual: IL spot-check & seal inspection,” “Quarterly: OTDR scan & closure integrity,” “Monthly: Physical damage & tension check”). The design uses soft background colors and minimal text to clearly convey the maintenance cadence for each environment.

A clean vector layout divided into four panels—Indoor Residences, Multifamily Dwellings, Outdoor Runs, and Industrial Sites—each with a simple icon. Beneath each icon are the recommended check intervals (“Annual: Visual inspection & V-FL test,” “Semi-annual: IL spot-check & seal inspection,” “Quarterly: OTDR scan & closure integrity,” “Monthly: Physical damage & tension check”). The design uses soft background colors and minimal text to clearly convey the maintenance cadence for each environment.

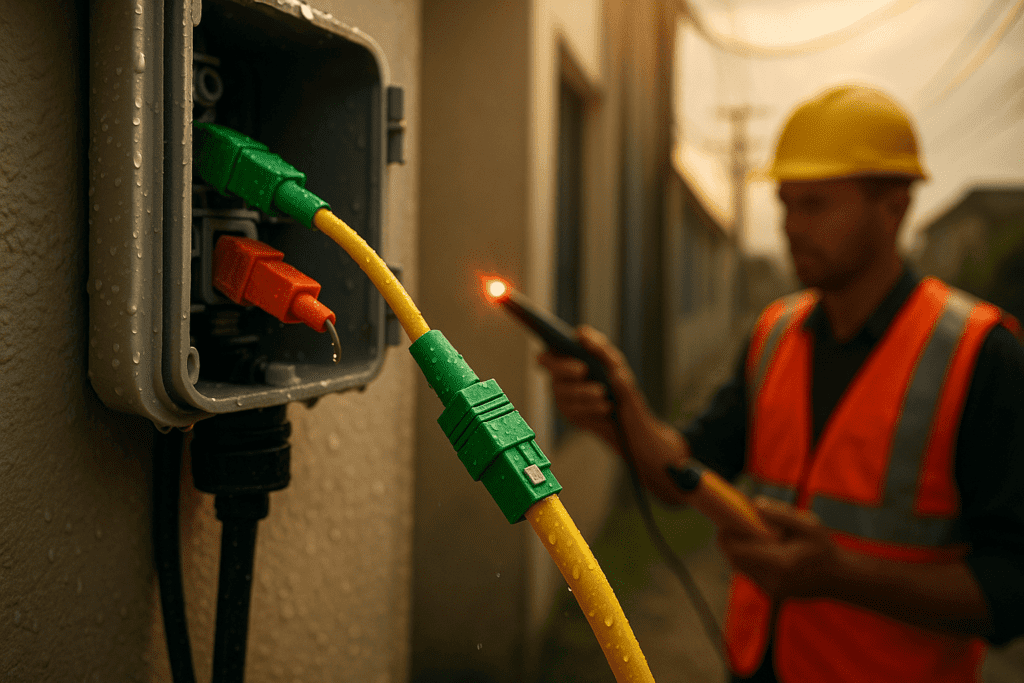

I once inherited a network where drop cables failed months after “perfect” installs. Over time, I developed a systematic maintenance and troubleshooting process to keep FTTH links reliable. In this article, we’ll cover routine checks, common fault causes, repair methods, and region-specific certification reminders (UL, ANATEL, CPR, CCC, etc.) to ensure your drop cables stay up and running.

1. Routine Maintenance Schedule

Establish a maintenance cadence based on environment:

| Environment | Frequency | Key Actions |

|---|---|---|

| Indoor Residences | Annual | Visual inspection, V-FL continuity test |

| MDUs & Risers | Semi-annual | IL spot-check, sleeve seal inspection |

| Outdoor Runs | Quarterly | OTDR scan, closure integrity check |

| Harsh/Industrial | Monthly | Physical damage inspection, tension check |

Tip: Log each check with date, technician, and measured IL/ORL values to spot trends.

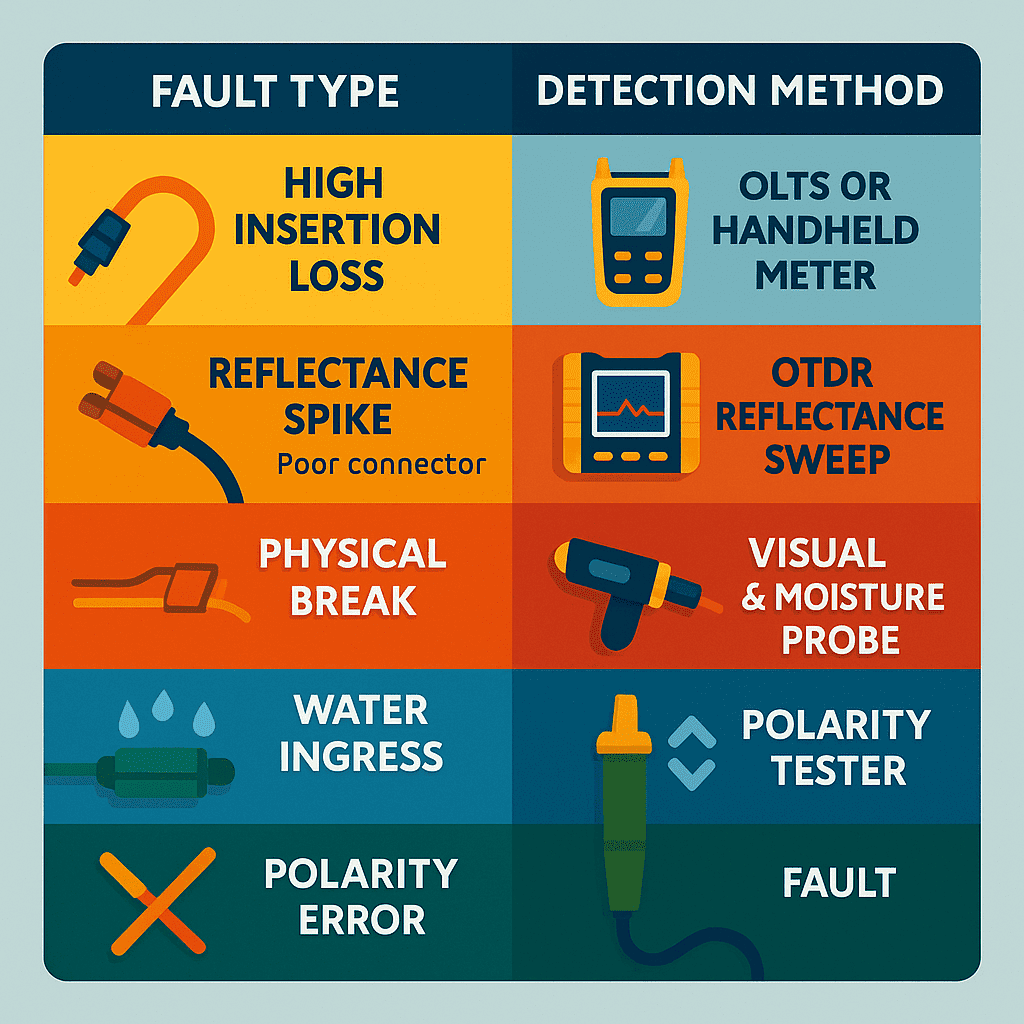

2. Common Fault Causes

| Fault Type | Likely Cause | Detection Method |

|---|---|---|

| High Insertion Loss | Dirt on connector, macro-bend, crush | OLTS or handheld meter |

| Reflectance Spike | Poor connector polish, micro-bend | OTDR reflectance sweep |

| Physical Break | Rodent damage, UV degradation, tear | V-FL scan |

| Water Ingress | Seal failure at splice or closure | Visual & moisture probe |

| Polarity Error | Incorrect patching or reversed pigtails | Polarity tester |

Example: A dusty splice closure caused 2 dB loss after a storm. Cleaning and resealing restored service.

3. Inspection & Cleaning Procedures

Connector Ferrules

- Remove dust caps; clean with dry cassette cleaner.

- Inspect under 200× scope; look for scratches or debris.

Splice Closures

- Open closure; remove any moisture-absorbing gel.

- Check O-rings and gaskets; replace if hardened.

Cable Sheath & Armor

- Inspect for cuts, dents, or corrosion (spiral armor).

- Verify UV-stable jacket integrity on outdoor runs.

Dive Deeper: Cleaning Checklist

| Item | Tool | Best Practice |

|---|---|---|

| Ferrule Cleaning | Dry cassette cleaner | Clean before and after every test |

| Closure Gasket Check | Silicone grease | Apply after resealing to maintain sealant |

| Armor Inspection | Bright flashlight | Look for exposed steel or cracks |

4. Testing & Verification Workflow

| Step | Tool | Criteria |

|---|---|---|

| Continuity Check | V-FL | No breaks or bends visible |

| IL Test | OLTS | ≤ original loss + 0.5 dB margin |

| ORL Test | OTDR reflectance sweep | ≤ −50 dB for SM connectors |

| Polarity Verification | Polarity tester | Tx→Rx mapping correct |

| Post-Repair Check | OLTS & V-FL | Return to baseline readings |

A flat, two-column grid with five rows. The left column lists Fault Types—High Insertion Loss, Reflectance Spike, Physical Break, Water Ingress, Polarity Error—each paired with a bold icon. The right column shows the matching Detection Methods—OLTS/Handheld Meter, OTDR Reflectance Sweep, Visual & Moisture Probe, Polarity Tester—also with icons. A contrasting color palette and rounded-corner boxes make it easy to match each fault to its testing tool at a glance.

A flat, two-column grid with five rows. The left column lists Fault Types—High Insertion Loss, Reflectance Spike, Physical Break, Water Ingress, Polarity Error—each paired with a bold icon. The right column shows the matching Detection Methods—OLTS/Handheld Meter, OTDR Reflectance Sweep, Visual & Moisture Probe, Polarity Tester—also with icons. A contrasting color palette and rounded-corner boxes make it easy to match each fault to its testing tool at a glance.

Note: In the US ensure UL-listed test equipment; in Brazil use ANATEL-approved meters; in EU verify CPR compliance on closure materials.

5. Field Repair Techniques

5.1 Connector Replacement

- Cut back 0.5 m; strip jacket and water-block layer.

- Use a factory-style mechanical/fusible connector rated to your region’s standard (e.g., UL 1651, IEC 61754).

5.2 Splice Closure Reset

- Clean old gel; re-gel fibers with manufacturer-supplied compound.

- Replace O-rings and reapply torque per spec.

5.3 Armor & Sheath Repair

- For minor sheath cuts, wrap with UV-stable self-fusion tape.

- For armor breaches, apply stainless-steel repair sleeve or replace section.

6. Certification & Compliance Reminders

| Region | Cable & Repair Standard | Notes |

|---|---|---|

| USA | UL 1651, UL 1666 | Indoor connectors and jacket ratings |

| Europe | CPR EN 50575 | Closure materials and tapes must be compliant |

| Brazil | ANATEL Technical Std. | All repair kits must be ANATEL-registered |

| China | CCC | Replacement components require CCC certification |

| Australia | RCM (AS/NZS 3080) | Test gear and repair materials must carry RCM |

Reminder: Always carry regional compliance documentation on site to speed up inspections.

7. FAQ

Q1: How quickly must I respond to a drop cable fault?

A1: Aim for 24-hour response in critical MDU sites; 48 hours in suburban residences.

Q2: Can I reuse a repaired cable section?

A2: Yes if IL & ORL return to within original spec + 0.5 dB margin.

Q3: What’s the best repair connector type?

A3: For indoor use, UL-listed mechanical LC; for outdoor, fusion-style sealed connectors.

Conclusion

Proactive maintenance and structured troubleshooting keep FTTH drop networks performing at peak reliability. By following this guide—inspecting connectors, testing losses, and making compliant repairs—you’ll reduce outages and extend cable life. For tailored maintenance plans or on-site training, reach out to me, Sophie Wang at AIMIFIBER. Let’s ensure your fiber always shines.