As technology continues to evolve, so does the need for high-performance fiber optic connectivity in tough environments. Whether you're managing large-scale telecom networks, deploying defense communication systems, or overseeing offshore projects, HXB Expanded Connectors offer a reliable and robust solution for your optical connectivity needs.

At Aimit Fiber, we understand the challenges faced by procurement managers, engineers, and project leads who require durable, easy-to-deploy fiber optic connectors that can withstand harsh conditions. This is why we recommend the HXB connector series, designed to ensure consistent performance and long-term reliability even in the most demanding environments.

What Makes HXB Expanded Beam Connectors Special?

The key to HXB connectors lies in their expanded technology, a revolutionary approach that transmits optical signals through collimated beams instead of direct fiber contact. This reduces the risk of contamination from dust, dirt, and moisture—factors that can compromise traditional connectors. The result is minimal maintenance, increased uptime, and a much longer service life in rugged conditions.

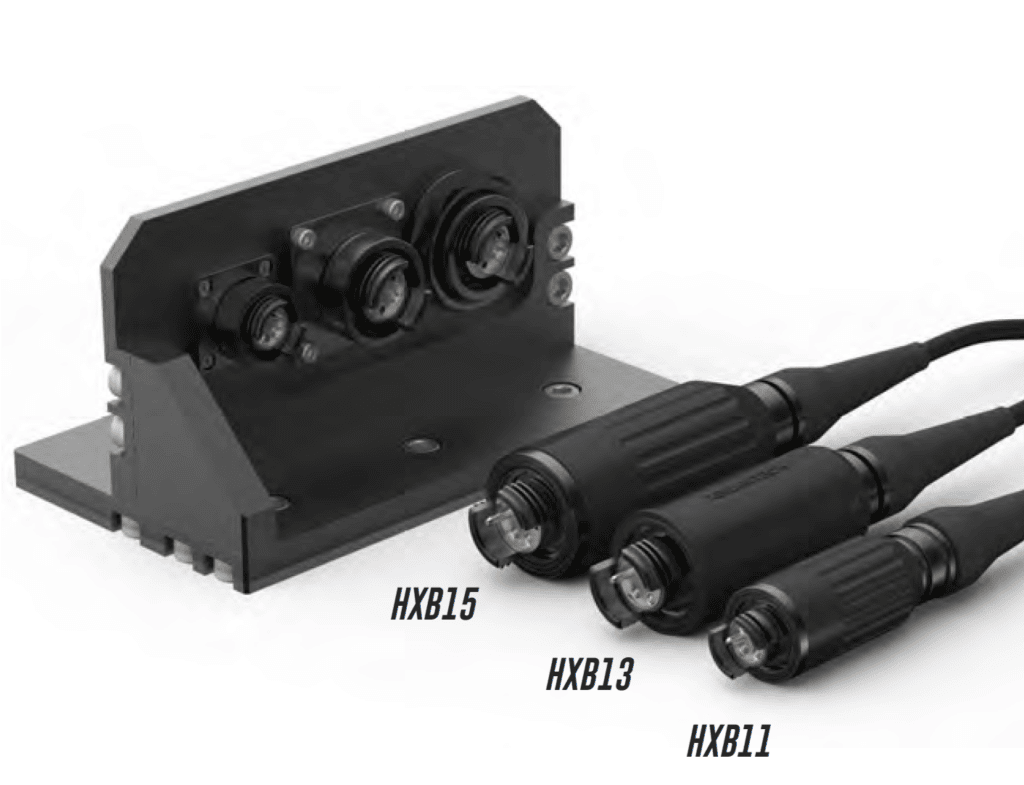

But that’s just the beginning. The HXB series offers a wide range of configurations, from 2-channel to 6-channel connectors, all while maintaining low insertion loss and exceptional return loss, ensuring high-quality data transmission with minimal interference.

Here’s why the HXB connectors should be your go-to for challenging environments:

- Hermaphroditic Design: This allows for easy interconnection between cables, simplifying field deployment and reducing the risk of mismatched connectors. It’s perfect for operations where time and efficiency are critical.

- Military-Grade Durability: HXB connectors are built to withstand extreme temperatures, vibration, shocks, and water immersion, making them ideal for field applications like tactical communications, mining, and offshore systems.

- Customizable Options: Whether you need single-mode or multi-mode configurations, HXB connectors come in multiple options tailored to your specific project needs.

Key Features of the HXB Connector Series

1. Robust Optical Performance

HXB connectors are known for their excellent optical performance, even in harsh environments. Here’s a quick overview:

| Parameter | Single Mode | Multi-Mode |

|---|---|---|

| Insertion Loss | 0.8 - 1.8 dB @ 1310, 1550 nm | 0.5 - 1.0 dB @ 850, 1300 nm |

| Return Loss | > 32 dB (Single Mode only) | N/A |

| Durability | 3,000 mating cycles | N/A |

With their expanded beam technology, HXB connectors significantly reduce the need for regular cleaning, which is essential in environments where downtime can be costly.

2. Designed for Harsh Environments

HXB connectors are designed to perform in extreme conditions. Whether it's -40°C winters or scorching 85°C summers, these connectors maintain their performance. Their IP68 rating means they are highly resistant to water immersion (up to 15 meters) and dust, making them perfect for outdoor or remote installations.

3. Flexible Configurations for Every Application

One size doesn't fit all, which is why the HXB series is available in multiple sizes and configurations. Whether you need 2-channel, 4-channel, or even 6-channel options, there’s a configuration that suits your needs. Additionally, HXB connectors support both single-mode and multi-mode fibers, making them versatile enough to fit into various data networks and communication setups.

Applications of HXB Connectors

HXB Expanded Beam Connectors are used across various industries due to their ability to withstand harsh environments. Here are some common applications:

- Defense and Military Operations: In high-stakes situations, military communications need to be reliable and robust. HXB connectors, with their rugged construction and ease of deployment, are ideal for tactical networks.

- Offshore and Subsea Systems: Offshore drilling and subsea operations demand equipment that can withstand both water immersion and high-pressure environments. HXB connectors, with their IP68 environmental sealing, deliver seamless performance in such conditions.

- Broadcasting in Harsh Conditions: From outdoor concerts to remote news broadcasts, reliable connectivity is crucial. HXB connectors offer the durability and easy deployment needed for live broadcasting in challenging environments.

- Mining and Industrial Applications: Dust, dirt, and vibration are common in mining environments, where downtime can cost millions. HXB connectors ensure reliable data transmission, minimizing the need for maintenance.

Frequently Asked Questions (FAQs)

1. What makes expanded beam technology superior in harsh environments?

Expanded beam technology uses collimated light beams to transfer data, eliminating direct contact between fiber ends. This reduces contamination from dust, moisture, and debris, making these connectors far more resilient and easier to maintain in harsh environments.

2. Can HXB connectors handle both single-mode and multi-mode fibers?

Yes, HXB connectors support both single-mode (SM) and multi-mode (MM) fibers, making them adaptable to different network configurations. Whether you’re working with long-distance data transmission or high-speed, short-range communications, HXB connectors have you covered.

3. How do HXB connectors perform in extreme conditions?

HXB connectors are designed to excel in extreme conditions. They operate efficiently in temperatures ranging from -40°C to 85°C and are resistant to water immersion up to 15 meters, vibration, and shock. This makes them a reliable choice for rugged outdoor and industrial environments.

4. What industries typically use HXB connectors?

HXB connectors are commonly used in defense, offshore oil and gas, mining, avionics, and broadcasting industries. They are ideal for any situation where high-performance optical connectivity is required under extreme environmental conditions.

5. How often do HXB connectors need maintenance?

Thanks to their expanded beam technology, HXB connectors require significantly less maintenance compared to traditional fiber optic connectors. In most cases, routine cleaning is not needed, which is a huge advantage in remote or hard-to-reach locations.