Your projects are falling behind schedule. Your teams are struggling with slow, error-prone on-site splicing in difficult weather, and every delay costs you money and damages your reputation. Pre-terminated fiber solutions offer a simple, powerful alternative for faster and more reliable network deployment.

Pre-terminated fiber solutions maximize uptime by replacing time-consuming field terminations with factory-tested, plug-and-play components. This approach drastically speeds up installation, minimizes human error, and ensures high performance from the start, getting your network online faster.

I remember a project in Brazil with a client, similar to Anson, who was under immense pressure to connect a new development. His team was stuck using traditional splicing methods, and they were losing valuable time. This experience showed me how pre-terminated solutions can be a true game-changer. Let's explore how.

What Are the Core Technical Advantages of Pre-Terminated Fiber?

The real power of pre-terminated fiber goes beyond just speed. The advantages are built into the technology itself, offering a more robust and reliable foundation for any network.

The core advantages are a modular deployment architecture using high-density connectors like MPO/MTP and guaranteed quality from factory testing. This results in lower signal loss, greater stability, and dependable performance, especially with advanced bend-insensitive fiber.

Dive Deeper: Lightweight and Modular Deployment

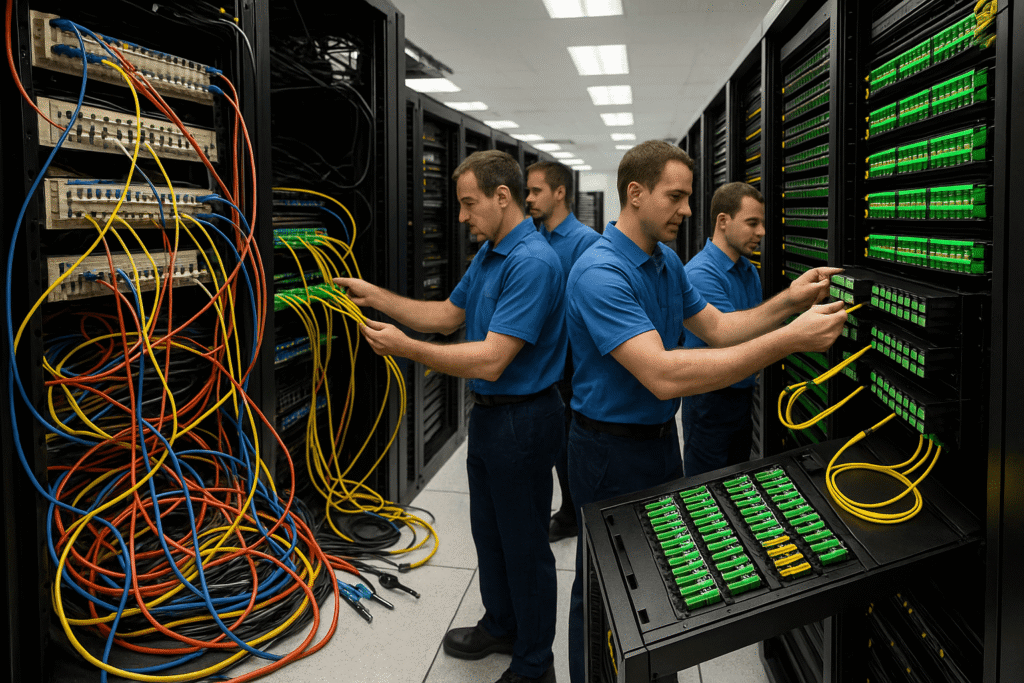

The old way of deploying fiber involves running individual cables and terminating each one by hand. This is slow and takes up a lot of space. Pre-terminated systems use a modular, building-block approach.

I often discuss this with clients like Yan from the US, who is very technically focused. He appreciates the precision of factory-made components. Instead of messy on-site work, his team can simply plug in a pre-built cassette or cable assembly.

Here’s a simple comparison of MPO/MTP connectors, which are central to this system, versus traditional connectors.

| Feature | MPO/MTP Connector | Traditional SC/LC Connector |

|---|---|---|

| Fiber Count | 8, 12, 16, or 24 fibers in one connector | 1 or 2 fibers per connector |

| Installation | Single-click connection | Individual connection for each fiber |

| Space Required | High density, saves rack space | Lower density, requires more space |

| Use Case | Data centers, high-density backbones | Patch panels, FTTH drops |

This modular design means you can build or expand your network much like snapping together building blocks, which is incredibly efficient.

For a deeper look at how modular pre-terminated fiber enables faster, scalable deployments, see Pre-Terminated Fiber Optic Components for Network Scalability.

Dive Deeper: Guaranteed Quality and Signal Stability

When you terminate a fiber optic cable in the field, the quality depends on the technician's skill, the tools, and the environment. I've seen projects delayed by rain or dust, which can ruin a splice.

With pre-terminated cables, all the critical connections are made in a clean, controlled factory environment. At AIMIFIBER, we perform rigorous tests on every single assembly before it ships.

- OTDR Testing: We use an Optical Time-Domain Reflectometer to check for any breaks or imperfections along the entire length of the cable.

- Insertion Loss (IL) & Return Loss (RL) Measurement: Every connector is tested to ensure it meets strict performance standards for low signal loss.

- Bend-Insensitive Fiber: We often use G.657 fiber, which can handle tight bends without significant signal degradation. This is something I always recommend for complex indoor installations.

This factory-controlled process eliminates the guesswork and ensures every component you receive is ready for high performance.

Discover more about the advantages of pre-terminated fiber optic cables and their impact on signal stability and reliability.

How Does Faster Installation Give You a Competitive Edge?

Time is money in our industry. Finishing a project faster isn't just a convenience; it's a powerful competitive advantage that helps you win more business and increase profitability.

Faster installation gives you a competitive edge by reducing labor costs and project timelines. This allows your company to handle more projects, react quicker to network repair needs, and submit more competitive bids.

Dive Deeper: Redefining the Deployment Workflow

Let's look at a practical example. Imagine you need to connect 1,000 ports in a new facility. A client in Europe, much like Andy from Spain, needs to meet strict deadlines for a major telecom tender. Using pre-terminated solutions is key for him.

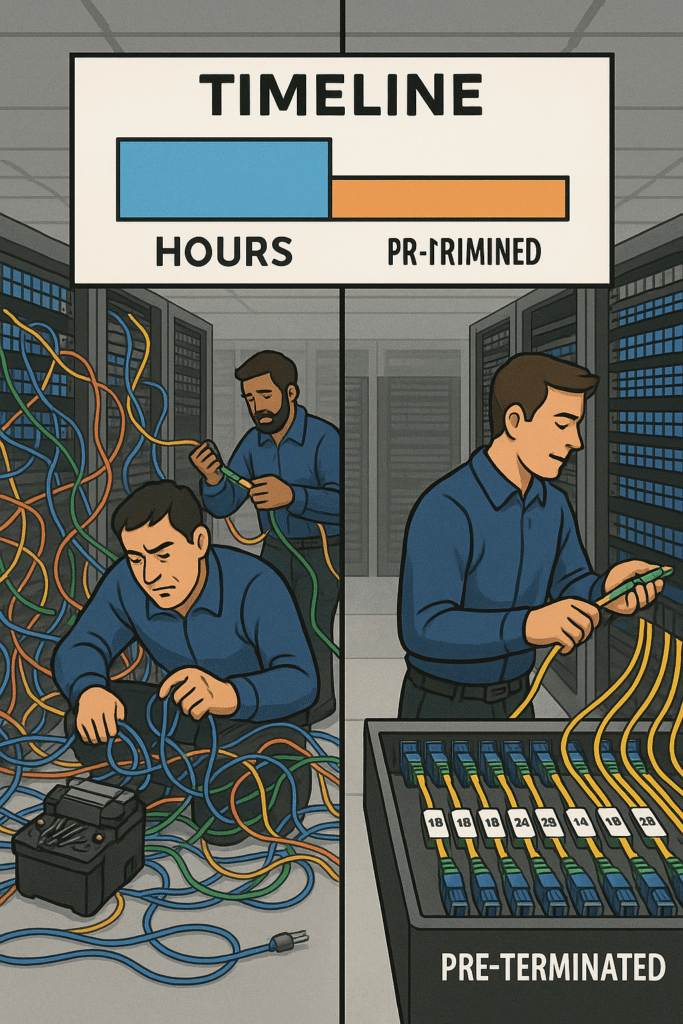

Here is a comparison of how the timeline might look.

| Deployment Task | Traditional Method (On-Site Splicing) | Pre-Terminated Method |

|---|---|---|

| Cable Pulling | 1 day | 1 day |

| Splicing/Termination | 3-4 days (for 1000 ports) | 0.5 days (plug-and-play) |

| Testing & Troubleshooting | 1 day (more potential errors) | 0.5 days (fewer errors) |

| Total Estimated Time | ~5-6 days | ~2 days |

As you can see, you can reduce the on-site workload by more than half. This frees up your skilled technicians to work on other high-value tasks.

To explore more about the benefits and cost savings pre-terminated fiber brings to deployment workflows, visit The Benefits of Pre-Terminated Fiber Cables.

Dive Deeper: Optimizing Costs and Resources

A faster workflow directly translates to lower costs. You need fewer specialized fiber splicers on-site, a role that requires expensive training and equipment. Instead, you can use general installation staff for the simple "plug-and-play" process.

Also, think about material waste. On-site termination always results in leftover cable cuts and consumable waste. Pre-terminated cables are manufactured to the exact length you need, which minimizes waste and helps control your project budget. This is a point that resonates with clients like Anderson in the competitive Brazilian market, where every dollar counts.

Final thoughts

Pre-terminated fiber is more than just a cable; it is a strategy. It boosts your efficiency, guarantees network reliability, and prepares you for the demands of tomorrow.