Your 5G network rollout is falling behind schedule. The demand for massive bandwidth from IoT and streaming services is relentless, but traditional fiber installation is slow and complex. On-site splicing creates delays, increases labor costs, and introduces performance risks. There’s a better way.

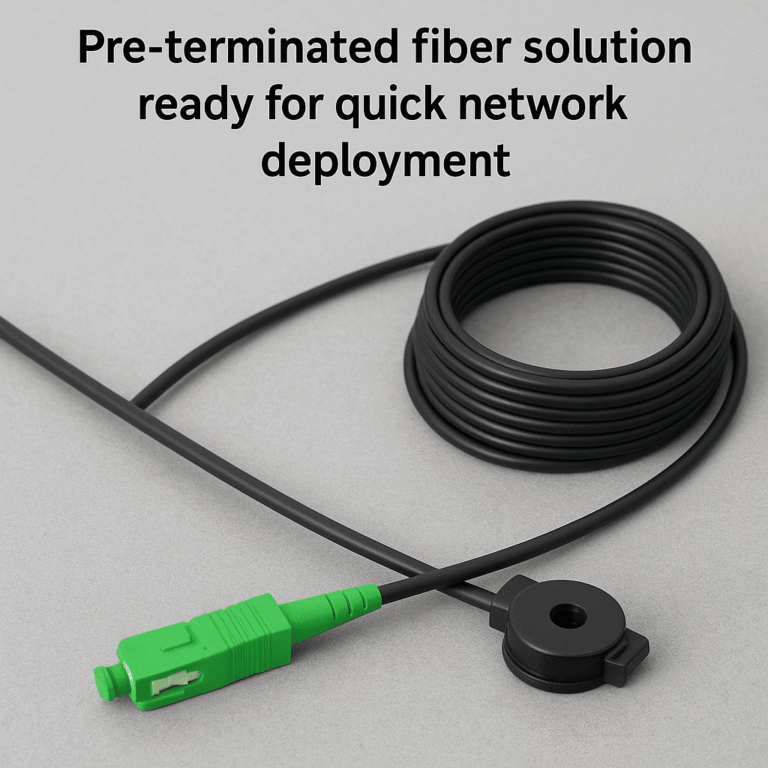

Pre-terminated fiber solutions revolutionize deployments by shifting complex termination and testing from the field into a controlled factory setting. This modular, plug-and-play approach ensures higher quality connections, dramatically faster installation times, and lower overall project costs.

I remember working with a project manager in Brazil, a client similar to Anson, who was under immense pressure. His company was losing market share in a competitive FTTH rollout because traditional deployments were just too slow. Switching to our pre-terminated solution was a game-changer for his project timeline. Learn more about the advantages of pre-terminated fiber optic cables.

Why Is Pre-Terminated Fiber a Game-Changer for Network Architecture?

The real magic of pre-terminated fiber isn't just about the cable itself. It’s about completely rethinking the system architecture. It simplifies the entire process from planning to deployment.

Pre-terminated solutions build a modular, plug-and-play network architecture. This allows for rapid, error-free deployments using factory-tested components like MPO/MTP connectors, which fundamentally changes how networks are built and scaled.

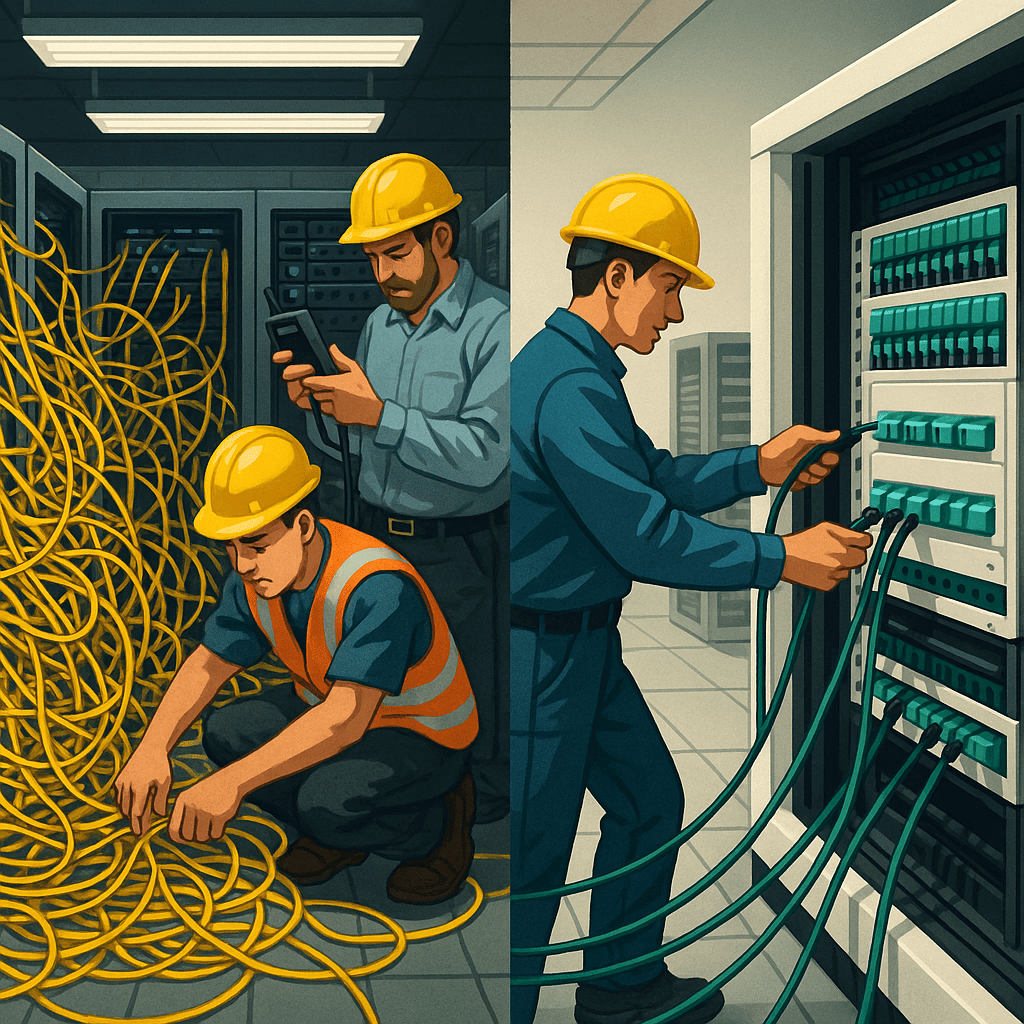

Dive Deeper: From On-Site Chaos to Factory Precision

With traditional fiber, highly skilled technicians need specialized tools for splicing and testing in the field. This process is time-consuming and vulnerable to weather conditions, dust, and human error. Every splice is a potential point of failure.

I’ve seen projects delayed for days because of bad weather or a single faulty splice that took hours to locate. Pre-terminated solutions eliminate this chaos. All the difficult work—polishing, epoxying, and testing—is completed in our clean, controlled factory environment. Your team on-site simply needs to plug the connectors together.

Dive Deeper: The Power of Modular Design

The modularity of this system is its greatest strength. Instead of rolls of cable and boxes of components, you receive pre-engineered assemblies ready for deployment. This includes solutions like modular Optical Distribution Network (ODN) units or high-density patch panels that can be installed and connected in minutes.

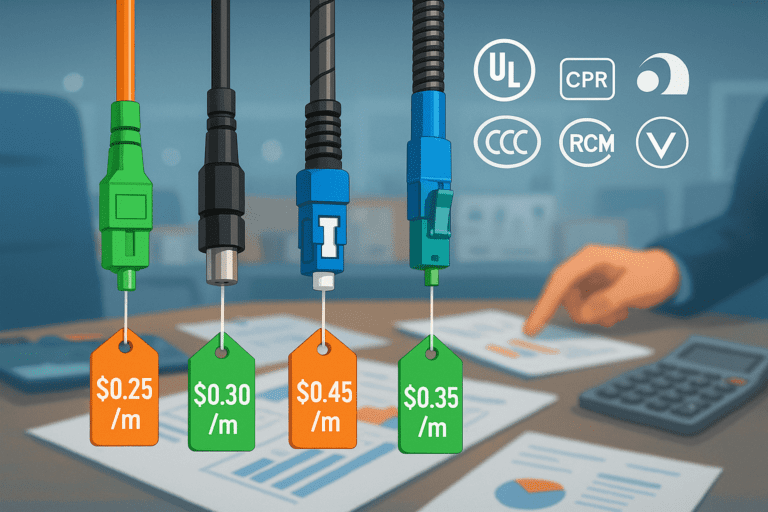

Here is a simple comparison:

| Technology Parameter | Traditional Solution | Pre-Terminated Solution |

|---|---|---|

| Installation Time | Several days | A few hours |

| Testing Efficiency | Multiple on-site tests | Factory pre-certified |

| Signal Attenuation | Higher, varies by splice | Lower, and consistent |

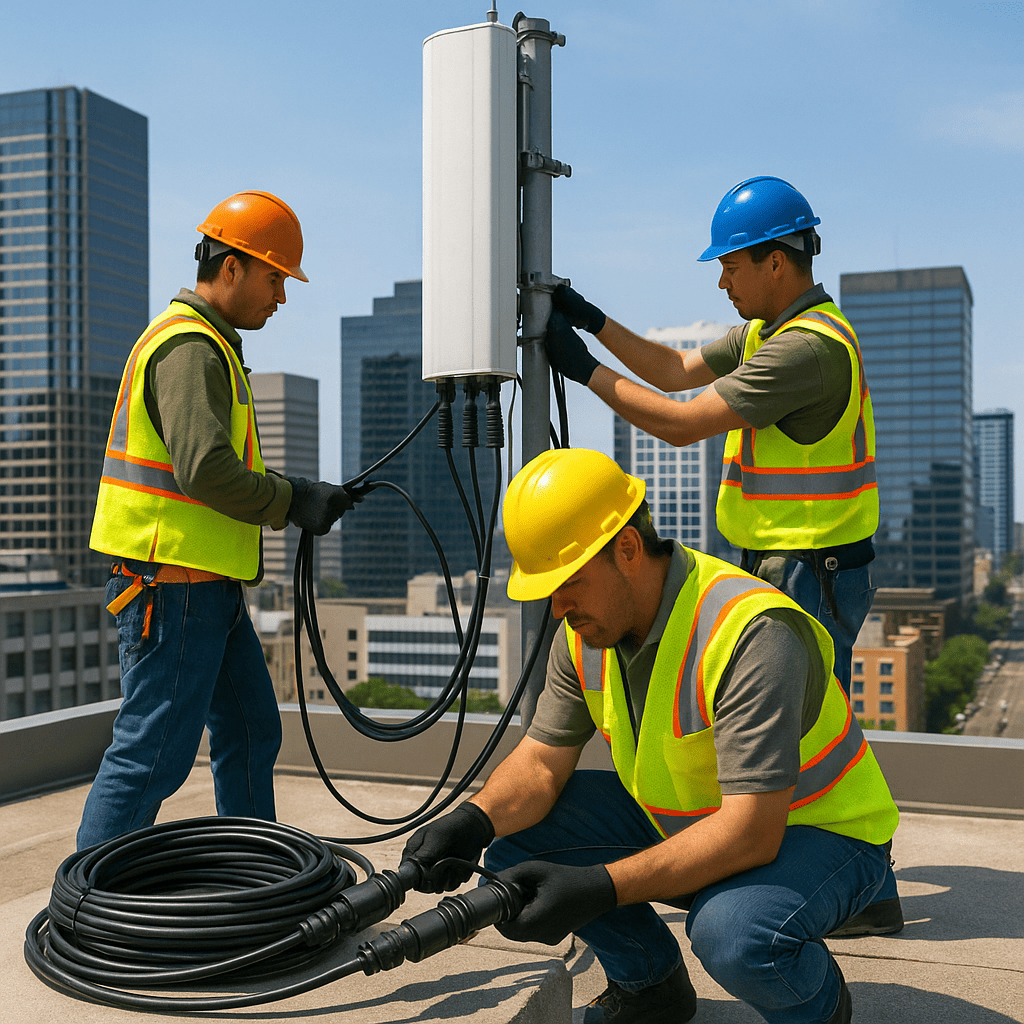

How Does This Technology Simplify 5G Site Deployments?

When deploying new 5G sites, the biggest challenges are speed and limited space. Project managers are always looking for ways to become more efficient, especially when dealing with hundreds or thousands of new locations.

For 5G sites, pre-terminated solutions cut on-site splicing by over 90%, drastically speeding up deployment. Factory-certified components eliminate complex field testing, ensuring a faster, more reliable "plug-and-power" installation process.

Dive Deeper: Accelerating Timelines and Reducing Labor

The most significant impact is on speed. Imagine telling your team that a site connection that once took a week of meticulous work can now be completed in a single afternoon. By replacing manual splicing with simple plug-in connectors, you reduce labor costs and minimize the need for specialized technicians on every site. A client in the U.S., much like Yan, told me this approach allowed his team to deploy three times as many sites in the same period. Discover key benefits of pre-terminated fiber cables.

Dive Deeper: Maximizing Tight Spaces

Real estate at cell towers and in base station hubs is expensive and crowded. Traditional cable management with its splice trays and excess cable loops takes up valuable rack space.

Pre-terminated systems use high-density connectors like MPO/MTP and are cut to precise lengths. This creates a much cleaner, more organized, and compact installation. Integrated ODN racks further consolidate the footprint, leaving more room for revenue-generating equipment. Explore high-density fiber optic cable selection.

Dive Deeper: Simplifying Maintenance and Troubleshooting

When a network goes down, every minute counts. With a traditionally spliced network, finding a fault with an OTDR can be a slow process of elimination.

With a modular system, maintenance becomes simple. If a component fails, you can quickly swap out the faulty module. Many pre-terminated systems also include designated monitoring points, making OTDR diagnostics faster and more accurate. This leads to faster recovery times and higher network uptime.

Final thoughts

Pre-terminated fiber is more than a product. It's a strategic shift that delivers the speed, reliability, and scalability required by modern networks, making it essential for the future of telecommunications.