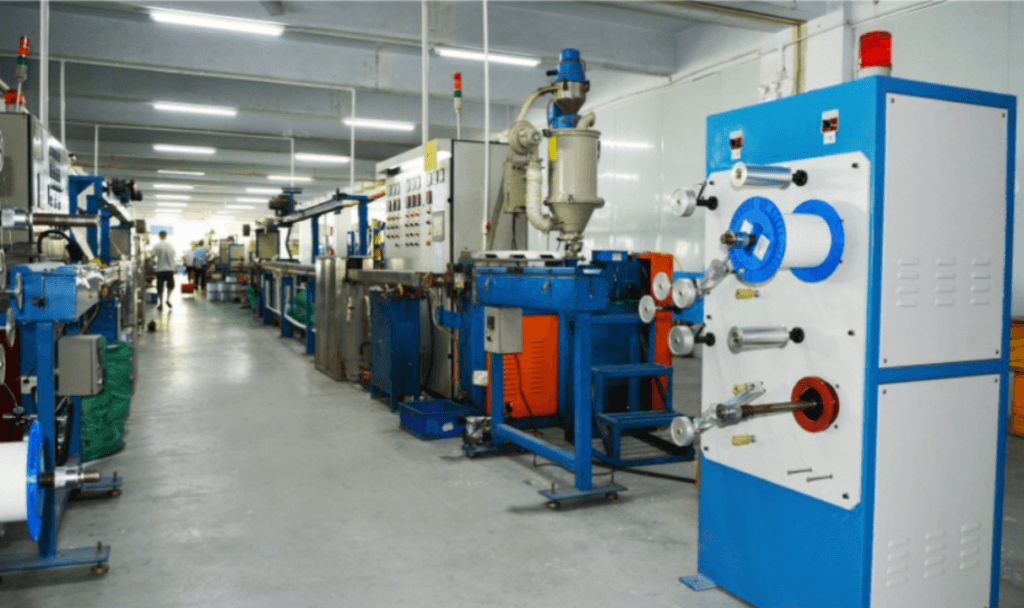

What is production equipment for fiber optic products?

Optical fiber and cable manufacturing equipment is designed and made for the production of optical fiber and cable products. It is an essential equipment for the production of optical fiber and cable. Optical fiber and cable manufacturing equipment are closely related to the optical fiber and cable industry.

Optical cable with light weight, good toughness, strong anti-seismic and cracking resistance, durable and reliable; No electromagnetic radiation, no electrical noise, strong anti-interference ability; Low maintenance cost, saving copper resources, low carbon energy saving and environmental protection; Simple installation, can be cut freely; Good coupling, strong light conductivity; High broadband, high speed, high performance; Good confidentiality, safe and reliable; Waterproof, moisture-proof, anti-magnetic, lightning and other advantages. Its application fields also extend from optoelectronic communication and sensor applications to medical applications and military applications.

The production of optical fiber and optical cable is a professional technical field, and the production of optical fiber and optical cable is completely different from that of most mechanical and electrical products. The production process of mechanical and electrical products is usually to assemble parts into parts, multiple parts and then assemble into a single product, and the product is measured by the number of units or pieces. The optical fiber, optical cable is the length of the basic unit of measurement, all optical fiber, optical cable is from the conductor processing, layer by layer in the outer layer of the conductor plus insulation, shielding, cable, protective layer and so on to make optical fiber and optical cable products, the more complex the product structure, the more layers of superposition.

The following is brief introduction of 30 types of Production Equipment for Optical Cable and Fiber Optic Assembly.

1. Optical Fiber Coloring&Rewinding Machine

Fiber optic coloring and rewinding machine is mainly used for SM, MM fiber full chromatography coloring, which is convenient for identification of multiple fibers in the beam tube, At the same time, the device can also be used in fiber rewinding segments.

The use of imported UV curing furnace, effectively improve the curing effect of coloring. The equipment is controlled by SlEMENS 300 series PLC from Germany. It has high automation and can operate more than one machine by one person.

2. Optical Fiber Secondary Coating Extrusion Line

The model is mainly used for extrusion production of 1- 12 core optical fiber filed Chinese pine bundle tube, and extrusion material is suitable for modifying benign PP and PBT.

Features:

Pay off adopts the active pay off device,the tension is stable and reliable, and the tension is adjustable.

Extruder adopts special screw, good extrusion linear, high extrusion efficiency.

Grease use professional except bubble filing device,in addition to bubble effect is good, oil filled device adopts precision metering pump, oil filled filing stability, oil supplement using precision weighing device, ensure timely supplement ointment.

Take-up adopts double bobbin automatic change bobbin, not slow down, automatic change bobbin, high production efficiency.

Control system adopts the international popular industrial computer control technology, automation is high, can link MES, ERF system, real-time tracking management production.

3. Optical Cable Sheath Extrusion Line

This equipment is mainly used for the extrusion of the inner and outer sheath of the optical cable.

Features:

Apply materials for PVC,LDPE,MDPE,HDPE,LSZH.

Temperature control adopts imported OMRON temperature control meter, and temperature control is accurate.

The production line system can automatically adjust the outer diameter of the wire diameter and the diameter stability through the diameter feedback function.

Control system adopts the international popular industrial computer control technology, automation is high, can link MES,ERP system, real-time tracking management production.

The main control systems and components using internationally renowned brands, production lines with high stability and reliability.

4. Distribution and Breakout Optical cable Sheath Extrusion Line

The equipment is mainly used for the production of indoor bundle, integrated wiring optical fiber cable (Optional:.cage stranding) and other products.

Features:

Precision special extruder and precision fine-tuning head, extruder applicable materials such as PVC and LSZH, PE and so on.

Wire diameter automatic feedback control, the diameter history curve can be traced back to query.

Active pay off. The tension is precisely constant with little additional loss.

Temperature control adopts imported OMRON temperature control meter, and temperature control is accurate.

Double bobbin automatic take-up, stable and reliable operation, one forming by automatic take-up and traversing, without rewinding.

Control system adopts the international popular industrial computer control technology, automation is high, can link MES,ERP system,real-time tracking management production.

5. Simplex/duplex Cable Sheath Extrusion Production Line

It is used to produce the sheath of2.0mm/3.0mm simplex/duplex cable, and extrusion material is LSZH or PVC.

Features:

Precise special extruder and precise fine-adjustment cross head, and extrusion material is PVC or LSZH.

Shape of final optical cable is smooth.

Can feedback and control diameter of optical cable automatically, the historical production curve of cable diameter can be inquired.

Active pay off, precise and stable tension, little additional loss.

Temperature controller adopt Japan RKC brand temperature controller to control accurately.6. Double bobbin automatic take up, work stably and reliably, traverse unit is automatic to finishing without rewinding.

Control system adopts international and popular industrial computer control technology, high automation, can ink MESERP system and track management production on-line.

6. FTTH Drop Cable Extrusion Line

This equipment is mainly used for extrusion production of FTTH ordinary butterfly fiber cable, and can produce butterfly fiber optic cables of various specifications such as 3.0*2.0mm, 5.0*2.0mm and so on.

7. Tight Buffered Fiber Extrusion Line

This equipment is mainly used for the production of compact fiber with indoor diameter 0.6mm and 0.9mm.

Features:

Precision special small extruder and precision fine-tuning head, the product of uniform diameter, with high degree of core,automatic diameter feedback, wire diameter curve records traceable inquiries.

The vacuum system of the vacuum pumping system is adjustable, and can be linked to the linear speed.

Active pay off,The tension is precisely constant with little additional loss.

Temperature control adopts imported OMRON temperature control meter, and temperature control is accurate.

Double bobbin automatic take-up, moving type take-up, stable and reliable operation.

Control system adopts the international popular industrial computer control technology, automation is high, can link MES,ERP system,real-time tracking management production.

8. CNC optical connector tension testing machine

CNC tensile testing machine is equipped with LED liquid crystal multi-point display for high-precision load element, using micro-processing control and integrated, digital measurement and control technology, and can process and print intelligent sensing material tensile stress, fiber optic cable tension test, is to help the industry control product quality status of the weapon.

9. Drop Cable Cutting Machine

Suitable for drop cable (butterfly drop cable) cable cutting process, customize the length of cutting meters, the number of cutting cables, touch screen display, simple and easy to understand.

Cable release speed, cable rewinding speed 0-10096 can be adjusted at will (6096 is recommended), cable diameter 160mm standard with other cable diameters can be customized.

The equipment has the functions of automatic alarm, slow start and slow stop, automatic wiring, stop buzzer and so on.

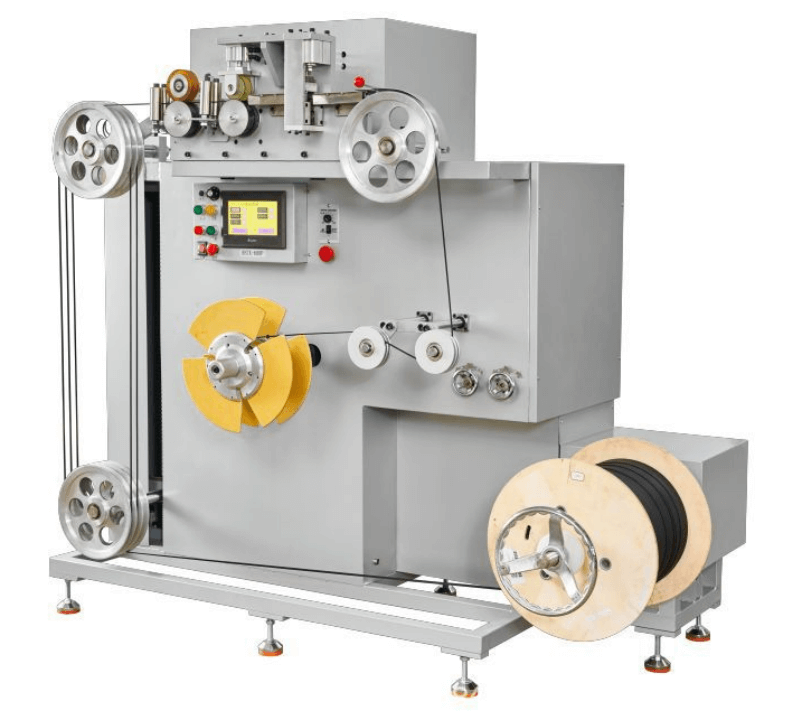

10. Cage winch equipment

It is suitable for indoor cabling of multiple optical fibers and 2.0/3.0 single fiber cable cabling.

11. Automatic Cutting Machine

It is suitable for optical fiber and cable cutting process, customize setting cable cutting length, cable cutting quantity, cutting times, medium stop (suitable for pigtail marking).

The cable release speed, the cable collection speed can be adjusted at 0-100% (60% is recommended), and the size and diameter of the drum can be adjusted arbitrarily.

The device has the function of automatic alarm, automatic length tracking memory, optical cable total length function memory, pigtail cutting, and code printing data and other functions.

12. Fiber optic polishing machines or Grinding Machines

Fiber optic polishing machines or Grinding Machine play an important role in fiber optic Patch Cord and Pigtail Production Line. It is also called fiber polisher.They are specially used in the fiber industry for polishing the end face of fiber optic connectors ferrule. In our fiber optic polishing catalogs, the polishing machine is versatile and be efficient and fast produced all kinds of standard fiber optic connectors type with dedicated.

13. Patch Cord Polishing JIG/Fixture/Holder

The optical fiber polishing Holder using high quality steel with heated treat, the hardened steel S136 provide long service life. This optical fiber polishing design SC, FC, ST, LC, MPO and E2000, FA, etc, according to the customer request.

The optical fiber polishing Holder is IPC Structure, Independent compression of each connector. The optical fiber polishing jig pass rate with Interference> = 98% (100% Typical, according to IEC), the optical fiber polishing jig APPEX OFFET is within 30. This optical fiber polishing jig is high stability and good surface quality.

14. Patch Cord Heat Curing Oven

Fiber optic heating Oven is to heating the fiber optic fiber and epoxy glue to be join together. There are two types of heat oven. One kind is for heating connector , another for heating the ferrule.

15. Fiber Optic Connector Crimper

Pneumatic Fiber Optic Connector Crimper is used for crimping the fixing rings of fiber optic connector to fix fiber optic cable jacket and Kevlar pneumatically when doing connectors and patch cord assembling in workshop.

This kind of Connector Crimping Machine for FC, ST, SC, MU, LC and E2000 Fiber Optic Connectors. It can be used in the fiber optic connector assembly and other product compression connection assembly, taking compressed air as power, Through solenoid valve control movement, the operation simple security.

16. RETURN LOSS & INSERTION LOSS Meters Testing Machine

We offers a range of return loss and insertion loss test equipment in single channel, multichannel and bi-directional configurations To Check the finished patch cable insertion loss and Return Loss in patch cord and pigtail production line .Insertion Loss (IL) and Return Loss (RL) Meters build on the well proven capabilities of the fastest RL meters in the industry.

17. Centrifugal Defoaming Machine

The centrifugal defoaming machine is a device used to remove bubbles from liquid materials, and its working principle is based on the action of centrifugal force. The centrifugal defoaming machine generates powerful centrifugal force by rotating the container, causing bubbles to separate from the liquid.

18. Fully Automatic Ceramic Core CNC Intelligent Special Glue Injection Machine

l Stable performance, and reliable quality

l Simple and convenient to operate, high-speed and accurate

l Chinese / English optional operation interface

19. Automatic Peeling Machine

The equipment has the functions of peeling the outer sheath, peeling and pressing the interface of the jacket, cutting the aramid at the same time, efficient and fast, saving the labor cost of this station. Aramid length, cable outer sheath, crimping opening, all can be adjusted.

20. SC connector assembly machine

Rapid pneumatic assembly of white shells. Save labor and time, in one step. Reduce the labor intensity of operators. Quality assured and durable.

21. Ceramic Ferrule Special Glue Scraping Machine

It can perform glue scraping on ceramic insert cylindrical bodies with diameters of 1.25mm and 25mm, increasing 3D grinding pass rate by 10%. A small device with significant utility.

22. Ultrasonic Cleaning Machine

Cleaning machine patch cord and pigtail manufacture line is a process that uses ultrasound (usually from 20–40 kHz) to agitate a fluid. The ultrasound can be used with just water, but use of a solvent appropriate for the object to be cleaned and the type of soiling present enhances the effect. Cleaning normally lasts between three and six minutes, but can also exceed 20 minutes, depending on which object has to be cleaned.

23. Microscope Checking patch cord and pigtail manufacture line

The fiber microscope used in inspecting the fiber optic connector end surface quality, this fiber microscope has high definition of inspection, fiber microscope is convenient and fast operation, precise and highly effective, the image is clear and bright, saves the time, reduces the cost. And this fiber microscope has strong function of applications, is your end of the optical fiber connectors detection of measuring tool. Ideal through the monitor display optical fiber connectors end of the image, and other fiber microscope, compared with common observation, can be in uniform inspection standard, which is beneficial to the related training and Technical personnel.

24. Visual Fault locator

A visual fault identifier or visual fault locator (VFI / VFL) is a visible red laser designed to inject visible light energy into a fiber. Sharp bends, breaks, faulty connectors and other faults will “leak” red light allowing technicians to visually spot the defects.

The VFI is an ideal tool for locating a large number of defects that occur at connection points in and around fiber cabinets which are hidden in an OTDRs “blind-spot” or dead-zone.

The laser-powered VFLis a cable continuity tester that locates fibers, verifies cable continuity and polarity. This cable continuity tester helps find breaks in cables, connectors, and splices. Continuous and flashing modes make for easier identification.

Applications:

Locate sharp bends, breaks, and damages in fiber

Conduct end-to-end continuity tests

Perform fiber tracing and identification

25. 3D interference Test Machine

The geometry of the end face or tip of fiber optic termini is a key factor for controlling the performance of the fiber optic connector. This geometry will determine which areas come into contact when two fiber optic connectors or termini are mated. This interference machine can generate an improvement guiding for polishing methodology In fiber . It includes the polishing pressure, polishing time, polishing speed, polishing grain size and polishing pad hardness. The computer support data collection, data printing , network data transmission etc.

26. Optical Fiber Identifier

Optical fiber identifiers (OFIs) are rugged, easy-to-use test instruments that detect the presence of signals on optical fibers. An OFI is an important tool for field technicians – assuring that live fibers are not disconnected and providing the ability to trace fibers from end to end.

27. Optical Fiber Ranger

Optical Fiber Rangers are a form of test equipment functioning similarly to an optical time domain reflectometer (OTDR).

The difference is that a fiber optic ranger is smaller in size and lightweight compared to an OTDR, and is generally considered a more cost-effective tool in analyzing and testing single mode fiber test applications.

Optical fiber ranger is test equipment that functions similar to an optical time domain reflectometer. It is used in single mode fiber test applications. The fiber optic ranger is much smaller size and lighter weight compared to the fiber optic OTDR, and it is much more cost effective. They are used in optical fiber links troubleshooting, maintenance and test.

28. Fiber Optic OTDRs

Fiber Optic OTDRs An Optical Time Domain Reflectometer is an important instrument used by organizations to certify the performance of new fiber optics links and detect problems with existing fiber links.

The OTDR sends a pulse of laser light into one side of the optical fiber. As the pulse travels along the fiber, a small portion of the pulse’s energy is reflected to the detector from points along the fiber, such as connectors, multiplexers, splices, splitters and other components on the optical link.

29. Optical Talk Set

Fiber optic talk set/Optical Talk Set consists of both the fiber optic light source and transceivers, which carry voice over the spare fiber in both directions. When doing the test work, technicians may need remote location communication during the measurement or splicing work, and sometimes radio-based communications may not be suitable because of environmental conditions such as FCC restrictions, etc. fiber optic talk set will function well in such cases, they could utilize the already installed fiber optic link to carry voice communications.

30. Optical Multimeter

Optical Multimeters,In the past, fiber optic power meter and fiber optic light source are two different type of fiber optic test equipment; they are usually used together to form the pair in the fiber optic test work. Fiber optic multi meter is a combo of the two, it combines the function of fiber optic power meter and fiber optic light source and the user can easily switch to choose the multi meter function via the control menu.

Conclusion

The characteristics of the production process of optical fiber and optical cable products are large length continuous combination production, many production process categories, large material flow, etc., it must be equipped with special production machinery with industry process characteristics to adapt to the structure and performance requirements of optical fiber and optical cable products, meet the requirements of large length continuous and high-speed production as much as possible, thus forming a series of optical fiber and optical cable manufacturing equipment products. Optical fiber, optical cable production process and the development of manufacturing equipment are closely related to each other and promote each other. Optical fiber, optical cable production process improvement and new process requirements, to promote the production and development of manufacturing equipment; The upgrading of manufacturing equipment and the development of new products have effectively improved the technological level of optical fiber and cable production, and promoted the promotion and application of new processes. The improvement of the quality of optical fiber and optical cable and the improvement of production efficiency cannot be separated from the technical improvement and innovation of manufacturing equipment.