How can enterprises effectively design and install a fiber optic cable system to ensure optimal performance?

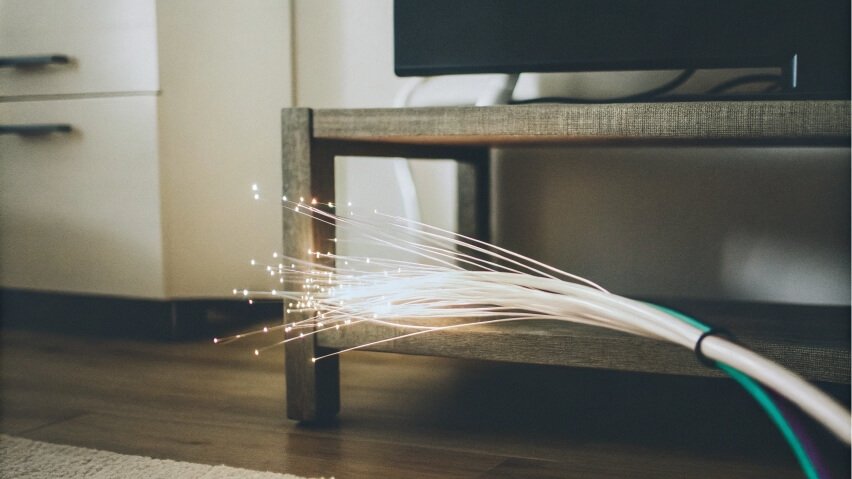

I see enterprise networks struggling with outdated copper wiring, random cable routes, and poor documentation. This leads to slow data speeds and complex troubleshooting. I know fiber optic network design best practices1 can fix these problems. With proper design and careful installation, I can build a scalable, efficient fiber infrastructure that supports all business needs.

Enterprises achieve optimal fiber optic performance by planning cable routes, selecting correct fiber types, installing quality connectors, and using proper tools. This involves careful design, structured pathways, secure enclosures, and skilled termination. With the right approach, businesses gain stable, high-speed networks that meet future bandwidth demands and simplify maintenance.

I remember advising a data center manager who struggled with messy cable trays and repeated signal losses. After implementing a structured approach aligned with TIA/EIA structured cabling standards2, using proper patch panels, and standardizing connector types, downtime dropped, and troubleshooting became easier. Let’s delve into the comprehensive steps, tools, and best practices for designing and installing enterprise fiber optic systems.

Why is a well-planned fiber optic cable system design critical for enterprises?

In my experience, a well-thought-out design prevents long-term headaches. Without careful planning, cables end up too long, tangled, or under stress. This can cause signal loss, downtime, and expensive fixes later. A structured design phase sets the foundation for a scalable, reliable, and easier-to-manage network.

Proper design ensures cables follow logical routes, avoid excessive bends, and meet bandwidth demands. It identifies fiber types, connector choices, pathway layouts, and installation hardware upfront. This preparation reduces wasted resources, enhances signal integrity, and streamlines future expansions or upgrades.

Good planning sets the stage for success. Next, we’ll consider where to place cables.

Where should fiber optic cables be installed for maximum efficiency?

By choosing the right pathways and protective conduits, enterprises safeguard cables from damage. Overhead trays, raised floors, and conduits keep fibers organized and accessible. Maintaining proper bend radius and separating cables from interference sources ensures stable, long-term performance.

Which components are essential for designing and installing an enterprise fiber system?

From fiber cables and connectors to patch panels, splice trays, and cable management accessories, each component plays a role. Selecting quality, standards-compliant parts leads to stable connections, less downtime, and easier upgrades.

What tools and equipment are required for fiber optic installation?

Skilled installers rely on fiber cleavers, fusion splicing best practices3, cable strippers, OTDRs, power meters, and polishing machines. With the right tools, splices and terminations achieve low loss, ensuring optimal link performance.

How to plan cable routes and ensure proper labeling?

Create route diagrams, identify pathways, and label cables at both ends. Clear labeling and documentation reduce guesswork, accelerate troubleshooting, and support quick modifications down the line.

What are the best installation practices for pulling, splicing, and terminating fiber cables?

Use recommended pulling tensions, respect bend radii, and apply proper cleaning and cleaving methods. Adhering to these best practices protects the cable’s integrity and ensures low-loss connections. For splicing, follow fusion splicing best practices. For advanced deployments, MPO MTP trunk cable installation4 guides offer tips on high-density solutions.

How do we test and validate the installed fiber network?

Insertion loss tests, OTDR measurements, and inspection of connectors confirm the network meets specifications. Thorough testing and documentation guarantee that the installed infrastructure is ready for live traffic.

How to maintain, document, and manage the fiber network post-installation?

Regular inspections, cleaning connectors, and updating records keep the network healthy. Document moves and changes in a central repository. This disciplined approach simplifies future upgrades or expansions.

How to scale and upgrade the fiber infrastructure for future needs?

Plan ahead by installing extra fibers, using modular components, and considering WDM fiber optic solutions5. MPO/MTP technology streamlines migrations to 40G/100G. Future-proofing reduces costs and downtime when bandwidth demands rise.

What safety precautions and compliance standards should be considered?

Comply with local codes, wear safety glasses, and handle fiber with care. For indoor applications, choose fire-safe cables, such as plenum-rated cable requirements6, or LSZH jackets. Compare LSZH vs PVC cable jackets7 to meet safety and regulatory standards.

Conclusion

I recall a time when messy installations, poor planning, and substandard tools resulted in a fragile, hard-to-maintain fiber network. After understanding fiber optic network design best practices and adhering to TIA/EIA structured cabling standards, I learned that designing and installing an enterprise fiber optic system requires careful planning at every step. Proper routing, labeling, quality components, correct termination techniques, and thorough testing ensure a robust and efficient network. Planning for scalability and compliance with safety standards further future-proofs the infrastructure. By following these guidelines and leveraging the right tools and standards, enterprises create stable, high-performance fiber networks that drive productivity and growth.

-

This resource provides comprehensive guidelines on designing fiber optic networks, ensuring optimal performance, scalability, and reliability for enterprise deployments. ↩

-

This resource outlines the TIA/EIA standards for structured cabling, essential for ensuring interoperability, performance, and compliance in enterprise fiber optic installations. ↩

-

This resource details the best practices for fusion splicing fiber optic cables, ensuring low-loss, high-quality splices crucial for network integrity. ↩

-

This resource offers a step-by-step guide on installing MPO/MTP trunk cables, facilitating high-density, scalable connections in enterprise data centers. ↩

-

This resource explores Wavelength Division Multiplexing (WDM) solutions, enhancing fiber optic network capacity and efficiency for enterprise applications. ↩

-

This resource explains the requirements and benefits of plenum-rated cables, ensuring fire safety and compliance in indoor fiber optic network deployments. ↩

-

This resource compares LSZH and PVC cable jackets, helping enterprises choose the right materials for safety, durability, and compliance in their fiber optic installations. ↩