How can fiber optic cable solutions enhance security surveillance systems?

I see many security projects that suffer from unclear video or unstable data connections. This leads to frustration and safety risks. I understand these pains. I want to share a clear, stable, and fast solution. Fiber optic cable solutions1 fix these issues and bring reliable surveillance to every corner.

Fiber optic cables improve surveillance by providing fast, stable data transfer. They resist interference, support long distances, and ensure clear video feeds. They help maintain security systems at scale. They deliver reliable transmission and meet strict quality needs. They solve common wiring issues and bring long-term value.

I remember when I first guided a client through a fiber-based upgrade. The difference was profound. The video clarity improved and system downtime reduced. This client, a major telecom buyer, thanked me later. I want to help you see the same results. Let’s dive deeper into these solutions.

Why choose fiber optic cable solutions for security surveillance systems?

I know many managers wonder if fiber cables are worth it. Fiber optic solutions provide stable links, long-range connectivity, and future-proof performance. With fiber, I can ensure minimal signal loss and robust security. I find that these benefits convince careful buyers to invest in better infrastructure.

Fiber optic cables offer far-reaching data links, stable bandwidth, and no interference from electromagnetic noise. They enable crisp and smooth video. They reduce maintenance costs. They provide a strong foundation for growing security networks. They ensure less downtime and better performance than traditional copper cables.

I see project managers focus on short-term costs. But fiber optic solutions pay off. I want to show a few angles:

Core Advantages of Fiber for Surveillance

- Distance: Traditional copper cables face signal loss over long runs. Fiber supports kilometers of stable transmission.

- Bandwidth: Fiber easily handles large amounts of data. High-definition video streams remain smooth.

- Interference Resistance: Unlike copper, fiber does not suffer from electromagnetic interference. This matters in factories, busy city streets, or high-voltage areas.

- Durability: Fiber cables resist harsh weather and demanding installations. Outdoor fibers, like ADSS cable2, handle aerial deployments without added metal supports.

Practical Comparison Table

| Feature | Fiber Optic Cable | Copper Cable |

|---|---|---|

| Max Distance | Up to kilometers | Few hundred m |

| Bandwidth Capacity | Very high | Limited |

| Interference | None | High risk |

| Durability | Strong (with right cable) | Moderate |

| Future Scalability | Easy | Hard |

| Maintenance Needs | Low | Higher |

This table shows why many decision-makers pick fiber. I often tell them, "Fiber sets a stable backbone for future expansions."

My Experience with Client Implementation

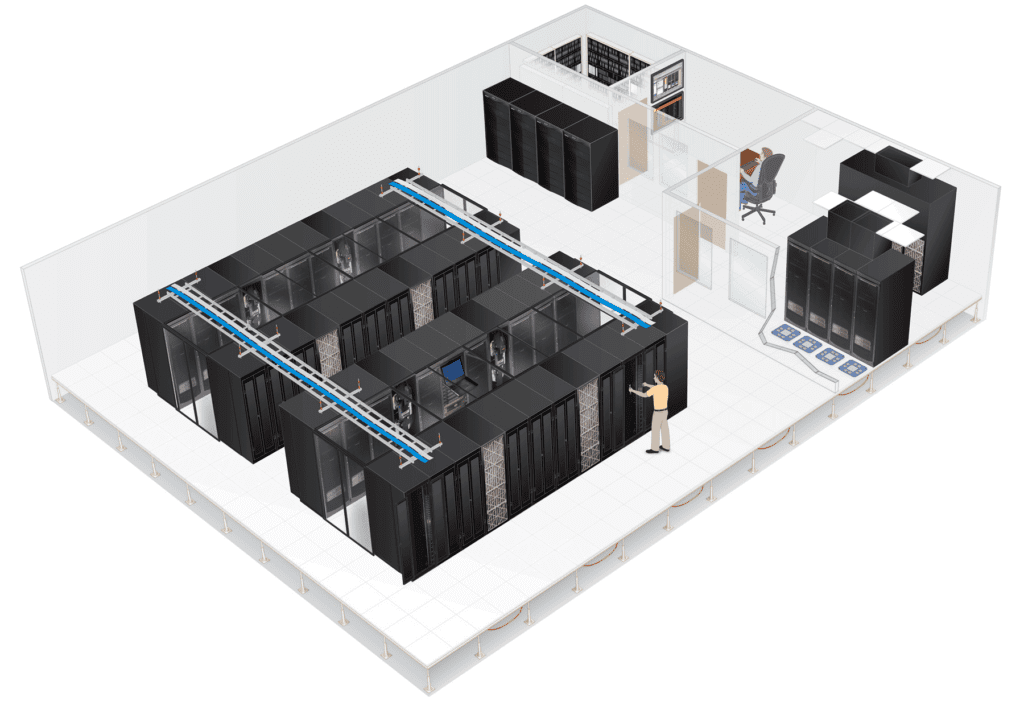

I recall working with a large data center that upgraded to MPO/MTP Trunk Cables3. They had issues with copper patch cords failing. With fiber trunks, the system stabilized. They handled huge data loads from multiple security cameras and sensors. They cut downtime and improved end-user satisfaction.

By now, we see that fiber offers a clear advantage. Next, we can explore detailed specifications.

What are the key specifications of fiber optic cables for security surveillance?

When I pick fiber optic cables, I always consider their specifications. Each project needs a certain fiber type, cable construction, and connector style. I know that these specs affect how your system performs. By understanding these specs, you make informed choices.

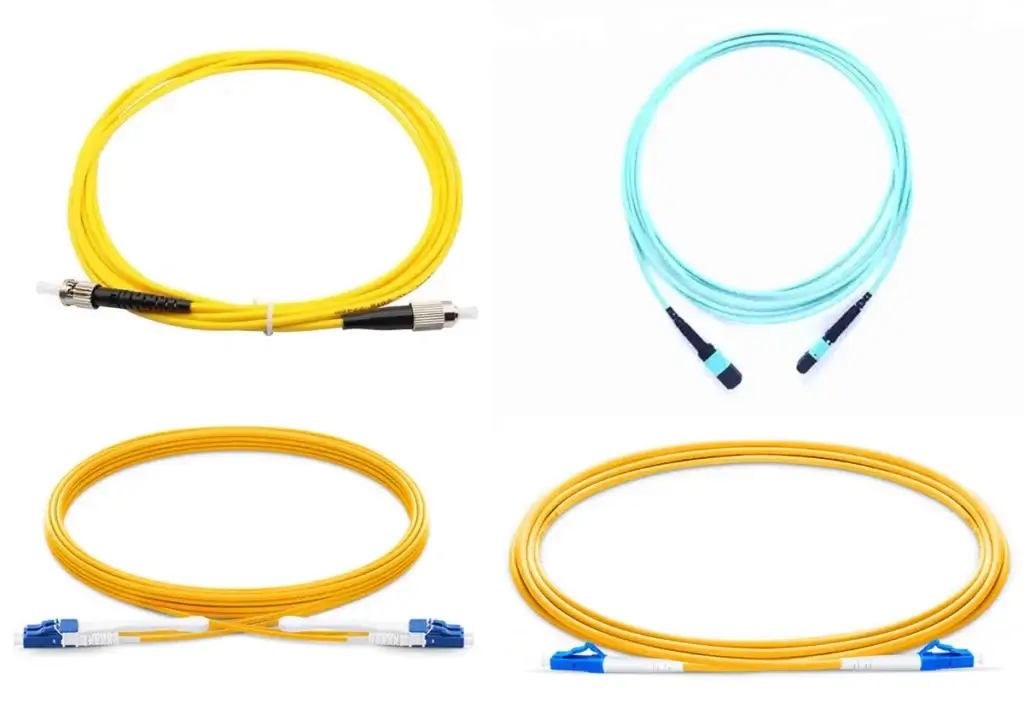

Key specs include fiber type (single-mode or multimode), cable construction (armored, ADSS, indoor/outdoor), connector type (SC, LC, MPO), and jacket materials (LSZH or PVC). These specs shape performance, durability, and simplicity. Picking the right specs ensures stable, long-lasting surveillance coverage.

Spec details matter. I break it down further:

Fiber Types

- Single-Mode Fiber (SMF): Ideal for long-distance transmission. It offers lower attenuation, making it great for large campuses or city-wide surveillance.

- Multimode Fiber (MMF): Often used for shorter distances. Easier to install and more cost-effective. Fits well in data centers, building-to-building links, or smaller sites.

Cable Constructions and Applications

- Armored Optical Fiber Cable: With a protective steel layer. Good for harsh environments with rodents or physical risks.

- ADSS (All-Dielectric Self-Supporting) Cable: Ideal for aerial installations. No metal parts. It can hang on poles without a separate messenger wire.

- Figure 8 Cable: Known for easy aerial installation due to its self-supporting design.

- Hybird Fiber Cable: Combines fiber and copper or power elements. Useful in remote camera locations that need power and data.

- Indoor Armored Fiber Cable: Designed for indoor use, protected but flexible.

- FTTH Drop Cable: Thin and simple for direct fiber-to-the-home connections. Perfect if you have cameras in residential complexes.

- MPO/MTP Cables: High-density solutions. Perfect for data centers with large camera arrays.

Connector Types and Standards

Common connectors for surveillance:

| Connector Type | Key Feature | Typical Use Case |

|---|---|---|

| SC | Simple push-pull | FTTH, patch panels |

| LC | Small form factor | High-density systems |

| FC | Threaded connector | Stable connections |

| MPO/MTP | Multi-fiber support | Data centers, large arrays |

Jacket Materials

- LSZH (Low Smoke Zero Halogen): For indoor use, safer in fires. LSZH cable4 standards ensure minimal toxic smoke.

- PVC: Common, cost-effective. More smoke than LSZH.

- Outdoor-rated (PE): Resistant to weather, UV, moisture.

Selecting the Right Specs

I suggest defining project distance, environment, and camera resolution. Then pick the cable that matches. For a city surveillance with long runs, single-mode outdoor cable works best. For a data center with high-density camera connections, MPO/MTP trunk cable shines.

After clarifying specs, we can see how these cables integrate into real scenarios.

How do fiber optic cables integrate into various surveillance scenarios?

I have seen fiber cables deployed in many settings. Urban intersections, long highway stretches, large stadiums, and secure government sites all need stable surveillance. Fiber’s low loss and interference-free performance handle these demands. By looking at real scenarios, we see how fiber fits everywhere.

Fiber cables support surveillance cameras across wide areas. They link cameras in smart cities, large campuses, industrial zones, and border areas. They handle HD video streams from multiple devices. They support remote monitoring, night-vision cameras, and advanced analytics. They make network scaling easier.

Common Deployment Scenarios

- Smart Cities: Fiber runs under streets connecting traffic cameras, facial recognition points, and emergency response sensors.

- Industrial Complexes: Factories use fiber for stable internal surveillance. The cables resist electromagnetic noise from heavy machinery.

- Border Surveillance: Long-range fiber lines connect remote camera posts. They deliver stable feeds to central monitoring stations.

- Campus Security: Universities and corporate campuses use fiber to link multiple buildings. One control room views all camera feeds.

Example Scenario Table

| Scenario | Cable Choice | Reason |

|---|---|---|

| Urban Intersection | Armored Outdoor Cable | Withstands rodent damage, weather |

| Long Highway Stretch | ADSS Fiber Optic Cable | Easy aerial deployment |

| Stadium Surveillance | MPO/MTP High-Density Cables | Connects many cameras in racks |

| Industrial Factory | Indoor Armored Cable | Resists mechanical stress, EMI |

| Border Monitoring | Single-Mode Outdoor Cable | Long-distance, stable performance |

My Personal Experience with a City Project

I once helped a client install ADSS cables along highways for traffic camera monitoring. We chose ADSS because no metal parts meant no extra support wire. We got stable HD video from cameras miles apart. It allowed city planners to track traffic flow and react faster.

By reviewing scenarios, we see that fiber fits into different setups. Next, let’s explore what applications can benefit most.

What applications can benefit from fiber optic cable solutions?

I know that surveillance isn’t just about cameras at a door. It spans airports, seaports, energy plants, data centers, and retail chains. Almost any application that needs reliable, high-quality video streams can benefit from fiber solutions. Understanding these niches helps target the best approach.

Airports, seaports, shopping malls, casinos, government offices, and data centers rely on fiber-based surveillance. They use fiber to ensure clear footage, real-time monitoring, and secure data channels. Fiber suits areas needing long-distance runs, zero interference, and high bandwidth for many cameras.

Diverse Applications

Airports and Transportation Hubs:

Many cameras monitor gates, runways, baggage claims. Fiber links these feeds reliably over vast terminals.Seaports and Coastal Areas:

Salt air and harsh weather demand rugged cables. Armored outdoor cables maintain stable connections over piers, docks, and warehouses.Energy Plants (Wind Farms, Oil Fields):

Fiber resists electrical noise. Perfect where heavy machinery runs. Maintenance crews get clear footage from safety areas.Retail Chains and Shopping Malls:

Fiber supports centralized monitoring. Large malls host multiple cameras, escalators, entrances, and parking lots. Fiber keeps all feeds stable.Government Security and Border Controls:

National security points rely on fiber. They need encrypted, stable connections over large distances.Data Centers and Telecom Rooms:

High-density MPO/MTP cables connect racks of cameras, sensors, and servers. Fiber’s bandwidth ensures smooth operation.

Application-Focused Table

| Application | Key Fiber Feature Needed | Cable Suggestion |

|---|---|---|

| Airport | Long distance, stable bandwidth | Single-Mode, ADSS cable |

| Seaport | Rugged, weatherproof | Armored Outdoor Fiber Cable |

| Energy Plant | EMI resistance, durability | Indoor/Outdoor Armored Cable |

| Mall/Shopping Centers | High-density connections | MPO/MTP Trunk Cable |

| Government Border | Secure, long-range transmission | Single-Mode Outdoor Cable |

| Data Center | High density, modular | MPO/MTP Patch Panel & Cable |

Personal Story from a Seaport Project

I once helped a seaport in South America implement Figure 8 cable for their perimeter cameras. The heavy winds and saltwater exposure needed a reliable cable. After installation, camera feeds showed stable quality. The port’s security team praised the consistent footage.

With these applications in mind, we must next consider how to choose the right supplier.

How to select the right fiber optic cable supplier?

I know picking a supplier can be tricky. We need consistent quality, technical support, and flexible customizations. By knowing what to look for, we avoid future headaches. The right supplier offers stable supply, R&D support, and global delivery experience.

Look for a supplier with strong production capacity, quality certifications, custom OEM/ODM services, and technical expertise. They should have proven export experience, responsive customer service, and the ability to offer tailored solutions. Reliability, quality tests, and on-time delivery matter most.

Criteria for Choosing a Supplier

| Criteria | Why It Matters |

|---|---|

| Production Capacity | Ensures timely delivery for large orders. |

| Quality Certifications | Guarantees product standards (e.g., ISO). |

| R&D Capability | Custom solutions, new product development. |

| Technical Support | Helps select right specs, trouble-shooting. |

| Global Export Experience | Smooth logistics and known shipping methods. |

| Warranty & After-sales | Safe fallback if issues arise. |

My Company and Experience

I, Sophie Wang, from Aimit Communication (Shenzhen) Co., Ltd (AIMIFIBER) offer comprehensive solutions. We have 16 production lines, 380 workers, and proven track records. We handle OEM/ODM and have a dedicated R&D lab. Our global clients trust us for stable supply, quality tests, and technical support.

Story of a Buyer from the US

A client from the US, a technical manager, once struggled with delayed shipments from other suppliers. When he turned to us, we delivered on time and provided custom FTTH drop cables that fit his project specs. He reported improved efficiency and fewer delays.

Building Long-Term Partnerships

Focus on long-term trust. A reliable supplier learns your needs, suggests better solutions, and speeds up your projects. This reduces stress over supply chain issues and creates room for scaling.

Choosing the right supplier sets the foundation for a smooth deployment.

What steps ensure the best deployment practices?

Even the best cables need proper installation. Good practices ensure stable performance. By planning carefully, testing before deployment, and following strict guidelines, I help clients avoid downtime and failures. Deployment steps matter as much as cable quality.

Follow structured installation steps. Conduct site surveys, map cable routes, secure splicing, polish connectors properly, and test signals at every stage. Use quality tools. Follow industry best practices. This leads to stable, long-lasting fiber installations that deliver top-notch surveillance output.

Recommended Installation Process

- Site Survey: Check distance, environment, obstacles, and cable paths.

- Cable Selection: Confirm specs based on requirements.

- Proper Handling and Pulling: Use correct pulling tension, do not exceed bend radius.

- Splicing and Termination: Use quality connectors, fusion splices, and ensure clean surfaces.

- Testing and Certification: Check optical power, insertion loss, and continuity with a power meter or OTDR5.

- Documentation: Record cable routes, test results, and component details.

Tools and Accessories Table

| Tool/Accessory | Purpose |

|---|---|

| Fiber Optic Stripper | Strips cable jackets cleanly |

| Visual Fault Locator | Locates fiber breaks or bending issues |

| Fiber Optical Power Meter | Measures signal power |

| Splice Sleeves | Protect spliced fibers |

| Fiber Patch Panel | Organizes and protects cable ends |

| Distribution Box | Houses splices and terminations |

My Experience with a Data Center Deployment

Once, I guided a data center client who needed to organize many MPO patch panels. We followed each step carefully. After testing, the entire system worked smoothly. The client appreciated the detailed documentation and easy maintenance. Following best practices saved future headaches.

With proper deployment, maintenance becomes simpler.

How do we handle maintenance, testing, and troubleshooting?

After installation, ongoing maintenance ensures consistent performance. I find regular testing, scheduled inspections, and proper cleaning extend cable life. Troubleshooting methods help quickly fix issues. With the right approach, fiber networks remain stable over many years.

Perform routine inspections. Clean connectors, test signal strength, and check for physical damage. Keep spare parts ready. Use OTDR tests to locate faults. Act fast when signals drop. Follow a maintenance schedule. This ensures stable, clear surveillance feeds without unexpected downtime.

Common Maintenance Tasks

- Connector Cleaning: Dust or dirt lowers performance. Use proper cleaning kits.

- Cable Inspection: Look for bends, breaks, or rodent damage.

- Signal Testing: Use power meters or OTDR to confirm signal quality.

- Firmware/Equipment Updates: Keep related devices (ONU, SFP modules, switches) up-to-date for best performance.

Troubleshooting Steps Table

| Problem | Possible Cause | Action |

|---|---|---|

| Low Signal Level | Dirty connectors | Clean and retest |

| Intermittent Loss | Faulty splices | Inspect, re-splice |

| No Signal | Break in cable | Use OTDR to locate break |

| High Attenuation | Incorrect cable | Verify specs, replace |

Example from a Field Technician’s Work

A partner once faced camera signal loss at a remote gate. We instructed him to use a Visual Fault Locator. He found a sharp bend causing attenuation. After adjusting the cable route, signals returned to normal. Regular checks and quick troubleshooting saved hours of downtime.

Maintenance keeps your network healthy for years. Next, we must consider future trends that will shape fiber solutions.

Which future trends will shape fiber optic solutions for surveillance?

Technology moves fast. I see growing demand for higher resolutions, AI-based analytics, and integrated IoT sensors. Fiber must evolve. Future fibers may support even greater bandwidth, simplified connectors, and smart monitoring. Staying aware of trends keeps you ready for tomorrow.

Upcoming trends include 8K video surveillance, AI-driven analytics, sensor integration for smart city ecosystems, and easier plug-and-play fiber connectors. Expect faster installation, advanced materials resisting tough conditions, and cables that adapt to next-gen protocols. Prepare now to stay ahead.

Higher Resolution and Bandwidth

As surveillance moves to 4K, 8K, or thermal imaging, bandwidth demand rises. Fiber can handle these needs. Next-generation fibers have even lower attenuation and support advanced transmission protocols.

AI and Edge Computing Integration

Cameras may process data at the edge. This reduces latency. Fiber links edge devices to central servers for deeper analysis. Expect fiber-compatible modules that simplify such deployments.

IoT and Smart City Sensors

Cities combine surveillance cameras with environmental sensors. Fiber supports both. A single cable might carry data from cameras, temperature sensors, and traffic counters.

Advanced Connectors and Modular Systems Table

| Trend | Expected Benefit |

|---|---|

| Pushable Fiber | Easier installation in tight spaces |

| MPO/MTP Evolution | Higher density, quicker setup |

| Hardened Connectors | Better outdoor reliability |

| Low-Friction Jackets | Faster pulling, less damage |

My Outlook

I see fiber’s role expanding as networks grow. Sophisticated patch panels, integrated distribution solutions, and custom cable assemblies will appear. As a supplier, I plan to offer more flexible, plug-and-play solutions. By anticipating these trends, I help my clients stay competitive.

Now, let’s wrap up everything we discussed.

Conclusion

The summary for the whole post:

I remember starting my journey in the fiber industry when many buyers hesitated to invest in fiber solutions. Over time, I saw how these cables solved quality issues, distance limitations, and interference problems. Today, fiber is a solid choice for security surveillance. It supports long distances, clear video feeds, and stable connectivity. From choosing the right specifications to picking a reliable supplier, every step matters. When installed correctly, fiber cables reduce maintenance costs, simplify scaling, and keep surveillance reliable. As we move toward higher resolutions, AI analytics, and IoT-driven smart cities, fiber stands ready to handle new challenges. I trust that by knowing the benefits, specifications, and best practices, you can build a secure, future-proof surveillance network. You have options like AIMIFIBER to guide you with tailored solutions, ensuring that your system grows with your needs. Whether you run a campus, a port, a data center, or a national telecom project, fiber optic cables are here to deliver stable, clear, and lasting security surveillance.

This resource helps readers understand in-depth how fiber optic solutions enhance surveillance systems, improving reliability, bandwidth, and clarity. ↩

This resource provides detailed guidance on ADSS cable features, installation methods, and best practices for stable, aerial fiber deployments. ↩

This resource explains the design, handling, and benefits of MPO/MTP trunk cables, ensuring efficient, high-density connections in surveillance setups. ↩

This resource clarifies Low Smoke Zero Halogen (LSZH) cable standards, safety benefits, and why they’re ideal for indoor surveillance installations. ↩

This resource covers how to properly use Optical Time-Domain Reflectometers (OTDR) for testing and troubleshooting fiber optic networks. ↩