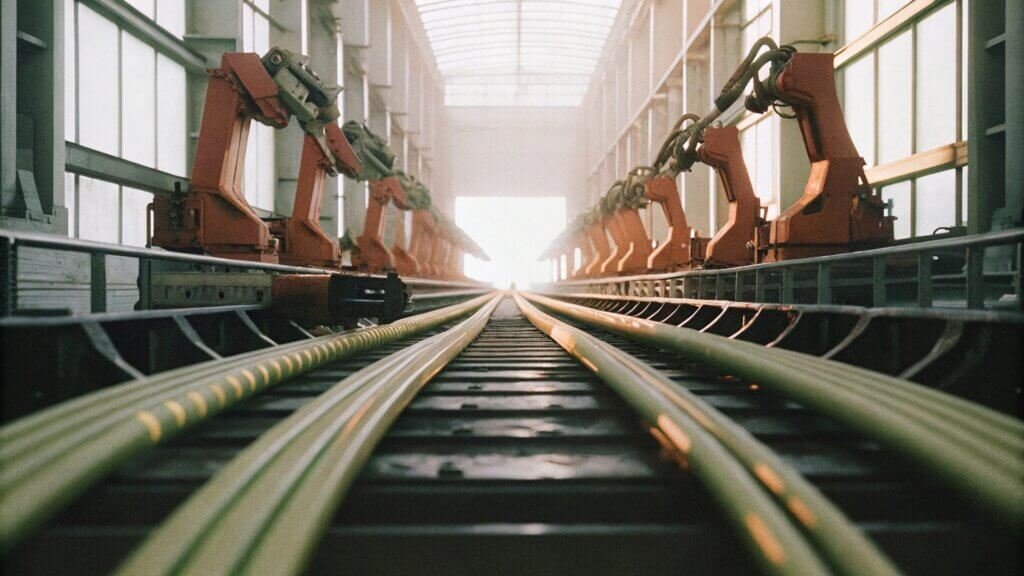

How Can Industrial Automation Fiber Optic Cable Solutions Enhance Your Operations?

Are you struggling with outdated wiring in your industrial automation systems1? It’s frustrating when inefficiencies slow down your production. Fiber optic cables2 offer a reliable solution.

Fiber optic cable solutions significantly improve data transmission speeds3 and reliability in industrial automation, leading to enhanced operational efficiency and reduced downtime.

I remember the first time we integrated fiber optics into our system. The transformation was remarkable, and it changed the way we approached automation.

What Are the Key Benefits of Fiber Optic Cables in Industrial Automation?

Fiber optic cables bring numerous advantages to industrial automation systems.

They offer high-speed data transmission speeds3, immunity to electromagnetic interference4, and enhanced security, making them ideal for demanding industrial environments.

Enhanced Data Transmission Speed

Fiber optic cables transmit data at the speed of light, ensuring rapid communication between devices. This speed is crucial for real-time monitoring5 and control in automation systems.

Immunity to Electromagnetic Interference

Unlike traditional copper cables, fiber optics are not affected by electromagnetic interference. This reliability is essential in industrial settings where machinery can generate significant electrical noise.

Improved Security

Fiber optic cables are difficult to tap into without detection, providing a secure means of data transmission. This feature is vital for protecting sensitive industrial data from potential breaches.

Benefits of Fiber Optic Cables

| Benefit | Description |

|---|---|

| High-Speed Transmission | Enables real-time data processing and decision-making |

| Electromagnetic Immunity | Ensures consistent performance in noisy environments |

| Enhanced Security | Protects data integrity and prevents unauthorized access |

| Long-Distance Transmission | Reduces the need for signal repeaters in large facilities |

| Low Latency | Minimizes delays in data communication |

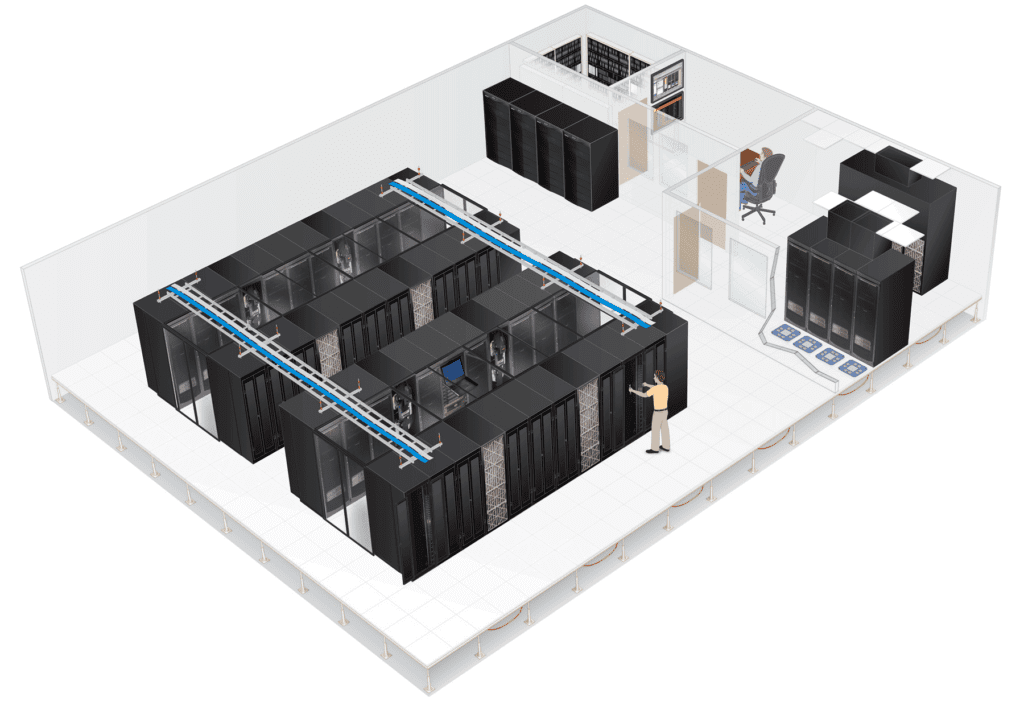

How Do Fiber Optic Cables Improve Data Transmission in Factories?

Efficient data transmission3 is the backbone of modern factories.

Fiber optic cables provide faster and more reliable data transfer, which is essential for seamless automation and control in manufacturing processes.

Real-Time Monitoring and Control

With fiber optics, factories can implement real-time monitoring systems that track production metrics instantly. This capability allows for immediate adjustments, enhancing overall efficiency.

Reduced Downtime

Reliable data transmission minimizes the risk of communication failures that can lead to equipment downtime. Fiber optic cables ensure that control systems remain operational, even in harsh conditions.

Scalability

As factories grow, their data transmission needs increase. Fiber optic systems are easily scalable, allowing for seamless expansion without compromising performance.

Data Transmission Improvements

| Improvement | Impact |

|---|---|

| Faster Data Transfer | Enhances responsiveness of automation systems |

| Increased Reliability | Reduces interruptions and maintenance needs |

| Better Signal Quality | Ensures accurate data for precise control and monitoring |

| Enhanced Bandwidth | Supports more devices and higher data volumes |

| Future-Proof Technology | Adapts to emerging technologies and increasing data demands |

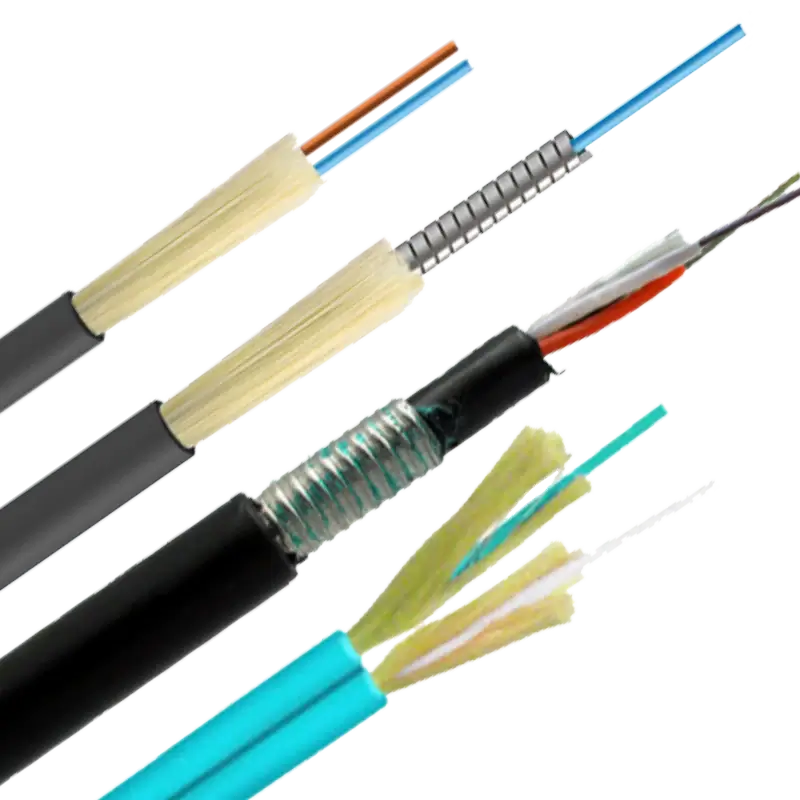

What Types of Fiber Optic Cables Are Best for Industrial Environments?

Selecting the right fiber optic cable is crucial for optimal performance in industrial settings.

Armored and rugged fiber optic cables2 are ideal for industrial environments due to their durability and resistance to harsh conditions.

Armored Fiber Optic Cables

These cables are protected by a metal sheath, making them resistant to physical damage. They are suitable for environments where cables may be exposed to mechanical stress.

ADSS Fiber Optic Cables

All-Dielectric Self-Supporting (ADSS) cables6 are designed for aerial installations. They are lightweight and resistant to environmental factors like UV radiation and temperature fluctuations.

Figure 8 Fiber Optic Cables

Figure 8 cables7 provide additional strength and flexibility, making them ideal for applications that require both durability and high-performance data transmission.

Fiber Optic Cable Types

| Cable Type | Best For | Key Features |

|---|---|---|

| Armored Fiber Optic | Industrial environments with high physical stress | Metal sheath, high durability |

| ADSS Fiber Optic | Aerial installations | Lightweight, weather-resistant |

| Figure 8 Fiber Optic | High-flexibility and strength requirements | Enhanced flexibility, robust design |

| Direct Burial Fiber | Underground installations | Waterproof, crush-resistant |

| Indoor Armored Fiber | Indoor industrial facilities | Protection against internal hazards |

How to Choose the Right Fiber Optic Solution for Your Automation Needs?

Choosing the right fiber optic solution requires understanding your specific automation requirements.

Assess your data transmission needs, environmental conditions, and scalability requirements8 to select the most suitable fiber optic cables for your industrial setup.

Assessing Data Transmission Needs

Evaluate the volume and speed of data your automation systems require. Higher data rates and larger volumes will necessitate higher bandwidth fiber optic solutions.

Considering Environmental Conditions

Industrial environments can be harsh. Choose cables that can withstand temperature extremes, moisture, chemical exposure, and physical wear and tear.

Planning for Scalability

Select fiber optic solutions that can grow with your business. Ensure that the cables and infrastructure can accommodate future expansions and technological advancements.

Factors to Consider

| Factor | Considerations |

|---|---|

| Data Volume and Speed | Required bandwidth and transmission rates |

| Environmental Conditions | Temperature, moisture, chemical exposure, physical stress |

| Installation Type | Aerial, underground, indoor, or outdoor |

| Future Scalability | Ability to upgrade and expand without major overhauls |

| Budget | Cost-effectiveness without compromising quality |

Conclusion

Fiber optic solutions revolutionize industrial automation by enhancing speed, reliability, and scalability.

Understanding industrial automation systems helps in appreciating how fiber optic solutions can optimize these environments. ↩

Fiber optic cables are essential for high-speed and reliable data transmission in industrial automation systems, enhancing overall operational efficiency. ↩ ↩

High data transmission speeds are crucial for real-time monitoring and control, which fiber optic cables provide in industrial settings. ↩ ↩ ↩

Electromagnetic interference can disrupt communication systems, but fiber optic cables are immune to such interference, ensuring reliable operations. ↩

Real-time monitoring allows for immediate adjustments in production processes, enhancing efficiency and reducing downtime. ↩

ADSS fiber optic cables are designed for aerial installations, offering durability and resistance to environmental factors, ideal for industrial use. ↩

Figure 8 fiber optic cables offer enhanced flexibility and strength, making them ideal for applications requiring both durability and high-performance. ↩

Planning for scalability ensures that fiber optic infrastructure can accommodate future expansions and technological advancements without major overhauls. ↩