How Do Standards and Regulations Shape Fiber Optic Cable Construction?

In the fast-evolving world of telecommunications, ensuring that fiber optic cable installations are safe, reliable, and efficient is paramount. Without adherence to strict standards and regulations, installations can lead to costly errors and potential hazards. Understanding and implementing these standards is essential for successful installations.

Fiber optic cable construction is shaped by a comprehensive set of standards and regulations that ensure safe, efficient, and reliable installations. These guidelines cover installation requirements, safety procedures, regulatory compliance, and specific cable specifications, providing a robust framework for telecom professionals to follow.

Imagine a world where the intricate web of fiber optic cables we depend on for high-speed internet and communication fails due to poor installation practices. Adhering to established standards and regulations is like following a trusted roadmap, guiding telecom engineers and product managers through the complexities of fiber optic installations.

What Are the Installation Requirements for Fiber Optic Cables?

The installation of fiber optic cables involves meticulous planning and execution to meet detailed standards and regulations. This ensures that the infrastructure is robust and minimizes potential disruptions in service. Understanding these requirements is crucial for telecom professionals seeking to maintain optimal performance and safety.

Installation requirements for fiber optic cables include detailed trenching and conduit guidelines, specific cable handling procedures, and adherence to safety measures. Following these ensures integrity, prevents damage, and protects installers, contributing to the overall reliability of the network.

Fiber optic cable installation starts with precise trenching and conduit laying. Trenches must be excavated according to detailed designs, ensuring a smooth, obstruction-free bottom. Conduits should maintain a minimum bend radius of 26 inches in 90-degree turns to prevent damage. Integrity proofing is vital before placing cables, with a minimum depth of 42 inches for conduits and at least one foot of separation from other utilities. Utility locates are essential to avoid conflicts, ensuring existing utilities' depths are verified before digging.

Trenching and Conduit Installation Techniques

- Design and Excavation: Trenches must follow detailed designs, ensuring a smooth, obstruction-free path.

- Conduit Placement: Avoid bends or kinks, maintaining a minimum bend radius of 26 inches.

- Depth and Separation: Ensure conduits are at least 42 inches deep with a foot of separation from other utilities.

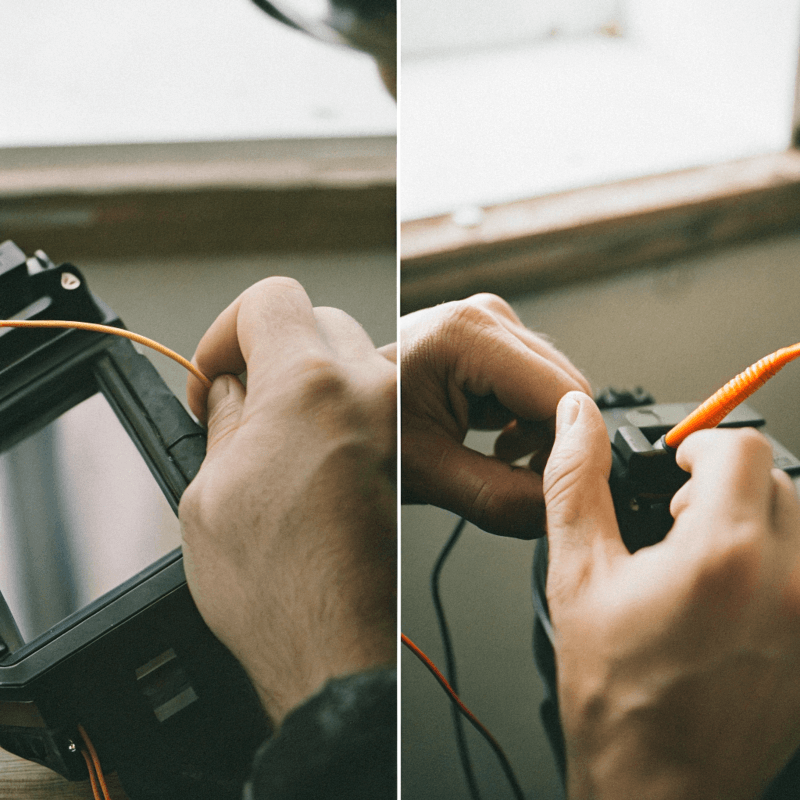

Cable Handling and Installation Guidelines

- Pulling and Pressure Limits: Cables should not exceed 600 pounds of pulling pressure or 150 feet per minute.

- Twist Prevention and Temperature: Avoid cable twists and maintain installation temperatures between -22 and 140 degrees Fahrenheit.

- Lubricants: Use recommended lubricants like Polywater or Hydralube to protect the cable sheath.

Safety Guidelines

- Protective Gear: Use safety glasses with side shields to prevent injuries from fiber shards.

- Regulatory Compliance: Adhere to OSHA and NESC guidelines for comprehensive safety during installations.

How Do Regulations and Standards Ensure Compliance in Fiber Optic Installations?

Regulations and standards act as the backbone of fiber optic installations, ensuring that every step of the process meets stringent safety and performance criteria. These guidelines are designed to protect both the infrastructure and the professionals involved in its installation.

Compliance in fiber optic installations is governed by several key standards and regulations, including the National Electrical Code (NEC), NECA/FOA-301, and OSHA regulations. These provide a framework for safe, efficient installation practices and ensure adherence to industry best practices.

The National Electrical Code (NEC), published by the NFPA, provides comprehensive guidelines for electrical design, installation, and inspection, including fiber optic cables. The NECA/FOA-301 standard, developed by NECA and FOA, outlines installation and testing practices, complementing other standards like TIA and ISO/IEC. OSHA's 29 CFR 1910.268 ensures compliance with minimum performance standards, with additional state-specific OSHA plans. For projects involving RUS loan funds, adherence to RUS Telecommunications Standards, outlined in 7 CFR § 1755.902, is essential.

National Electrical Code (NEC) Overview

- Purpose: Governs electrical design and installation, including fiber optics.

- Key Features: Comprehensive guidelines for safe and effective installations.

NECA/FOA-301 Standard Highlights

- Development: Created by NECA and FOA to guide fiber optic cable installations.

- Compatibility: Works in conjunction with other international standards.

OSHA and State Regulations

- Federal Guidelines: OSHA 29 CFR 1910.268 covers installation and maintenance.

- State Plans: States may have additional regulations to consider.

What Are the Cable Specifications for Different Fiber Optic Applications?

Fiber optic cables vary in design and specifications depending on their intended application. Understanding these differences is crucial for selecting the right cable type for specific installation needs, ensuring optimal performance and compliance with industry standards.

Fiber optic cable specifications include different types for various applications, such as aerial or underground, and specific color coding for fiber identification. These specifications ensure the cables meet telecommunications-grade standards and can be installed correctly.

Fiber optic cable types are tailored to specific applications. All Dielectric Self Support (ADSS) cables are designed for aerial installations, while Cable-in-Conduit types suit underground use. These cables must meet telecommunications-grade standards, often featuring specific fiber configurations, like 12 single-mode fibers for underground cables. Color coding, as per ANSI/ICEA S-87-640, ensures proper identification of fibers, crucial for accurate installation and maintenance.

Cable Types for Various Installations

- ADSS Cables: Ideal for aerial installations, providing robust support and reliability.

- Cable-in-Conduit: Designed for underground applications, ensuring protection and compliance.

Color Coding and Identification Standards

- Purpose: Ensures proper fiber identification and organization.

- Standards: Follows ANSI/ICEA S-87-640 for consistent identification.

%

Conclusion

In conclusion, the intricate world of fiber optic cable construction relies heavily on strict adherence to established standards and regulations. These guidelines cover every aspect of the installation process, from trenching and conduit placement to cable handling and safety measures. By following these standards, telecom professionals can ensure their installations are safe, reliable, and efficient, ultimately leading to a more robust telecommunications infrastructure. Understanding and implementing these regulations is not just a legal requirement but a crucial step in delivering high-quality, dependable fiber optic networks. As the demand for faster, more reliable internet grows, so too does the need for meticulous compliance with these standards, ensuring that the backbone of our digital communication remains strong and resilient.