How Do You Select the Right Fiber Optic Cable Equipment1?

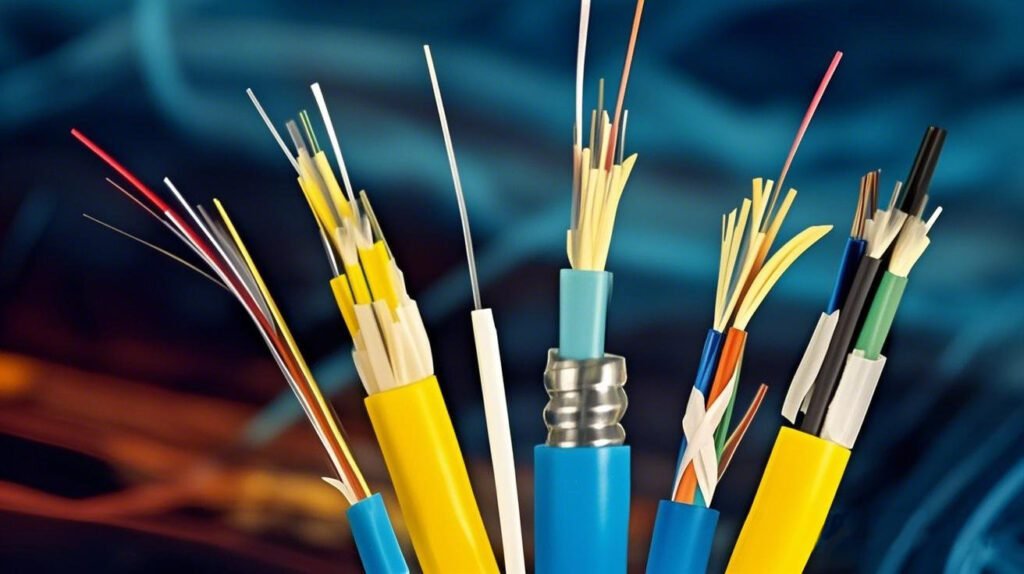

Selecting the right fiber optic cable equipment can be a daunting task. Often, the wrong choice leads to inefficiencies and increased costs. But what if you could ensure optimized performance and reliability by making informed decisions? Let’s explore how to make the right choices for your fiber optic needs.

Choosing the right fiber optic cable involves considering various factors such as fiber type, cable jacket, connectors, and installation requirements. By evaluating your specific needs and application environment, you can ensure efficient and reliable fiber optic connections.

Imagine a world where your network infrastructure seamlessly supports burgeoning data demands. This vision is possible by choosing the right fiber optic cable equipment. Let’s dive into the essential factors that can guide your decision-making process and help you achieve a robust telecommunications network2.

What Factors Should You Consider When Choosing Fiber Type and Length3?

When selecting fiber type and length, it's crucial to understand your specific application needs. Multimode fibers are suitable for short distances and high bandwidth, while singlemode fibers excel over longer distances. Your choice impacts not only performance but also cost-efficiency and future-proofing.

Choose multimode fibers for short distances and high bandwidth applications, and singlemode fibers for long distances and high-speed requirements. This ensures optimal performance and cost-efficiency based on your specific needs.

Fiber optics offer various types like multimode (OM1 to OM54) and singlemode (OS1/OS25). Multimode fibers work well within data centers, offering up to 100G over 150 meters with OM5, while singlemode supports long-haul communications. Consider network speed, application scope, and future expansion when choosing fiber type.

What Are the Considerations for Cable Jacket Type?

The cable jacket protects the fibers and should be chosen based on installation environment. Indoor and outdoor deployments require different materials to withstand variables like temperature, moisture, and chemicals. The right jacket ensures durability and performance.

Choose your cable jacket based on installation environment. Indoor cables require flexibility and fire resistance, while outdoor cables need strength and environmental resistance to ensure long-lasting performance.

Cable jackets come in various materials like PVC for indoor6 use and PE for outdoor7 applications. Consider the environment: indoor requires flexibility and fire resistance, while outdoor demands robust materials against weather and chemicals. Proper jacket selection prevents damage and extends cable lifespan.

How Do Connectors Impact Fiber Optic Cable Selection8?

Connectors are vital for connecting cables to devices or panels. Selecting the right type, such as LC, SC, or MPO9, ensures compatibility with equipment and ease of installation, affecting both performance and maintenance.

Match connectors like LC, SC, or MPO with your equipment to ensure compatibility and optimal performance. This simplifies installation and maintenance, crucial for efficient network operations.

Connectors like LC (small form factor)10 and SC (push-pull11) cater to different needs. MPO connectors serve multi-fiber cables, ideal for data centers. Consider equipment compatibility and future needs when selecting connectors, ensuring seamless integration and minimal downtime.

Why Is the Number of Fibers12 Important?

The number of fibers in a cable determines its capacity and potential for expansion. Installing more fibers than currently needed can accommodate future growth and backup needs, ensuring scalability.

Install more fibers than needed to allow for network expansion and backups. This future-proofing strategy ensures scalability and reduces future costs.

Fiber count affects capacity and expansion possibilities. Consider current and future needs, application type, and potential upgrades. More fibers now can prevent costly retrofits later, offering flexibility and resilience in network design.

What Are the Key Installation Requirements?

Proper installation is key to cable performance. Adhere to guidelines like maximum pulling load ratings and vertical rise limits to prevent damage. Outdoor installations must account for environmental changes impacting cable integrity.

Follow installation guidelines such as pulling load limits and environmental considerations to prevent fiber damage and ensure optimal cable performance.

Installation involves mechanical considerations like tensile strength and bending radius. Ensure compliance with standards to avoid breakage, especially in harsh environments. Outdoor cables need allowances for temperature shifts to prevent attenuation, ensuring reliable connections.

How Do Environmental Conditions Affect Fiber Optic Cables?

Environmental conditions directly impact cable performance. Choose cables designed to withstand factors such as temperature extremes, moisture, and chemicals to maintain long-term reliability.

Select cables that withstand environmental challenges like temperature, moisture, and chemicals. This ensures durability and consistent performance in various conditions.

Environmental factors like temperature, moisture, and chemicals can degrade cables. Opt for robust designs, such as armored cables for harsh conditions, ensuring reliability and longevity. Evaluate installation site conditions to choose suitable materials, preventing performance degradation.

Why Is Compatibility with Existing Infrastructure Crucial?

Compatibility with existing infrastructure ensures seamless integration and functionality. Matching fiber size with device specifications prevents connectivity issues, optimizing network performance.

Ensure compatibility with existing infrastructure by matching fiber size with device specifications. This prevents connectivity issues and optimizes network performance.

Infrastructure compatibility involves matching fiber size with transmitters and receivers. Mismatched components cause signal loss and inefficiency. Evaluate current infrastructure and equipment to select compatible fibers, ensuring seamless integration and operational efficiency.

How Do Cost and Future-Proofing Influence Your Choices?

Balancing cost with future-proofing is essential. While budget constraints are a reality, investing in higher bandwidth capabilities and additional fibers can save costs long-term by reducing the need for future upgrades.

Balance cost with future-proofing by selecting higher bandwidth cables and additional fibers. This minimizes future upgrade needs, optimizing long-term investment.

While cost is a factor, future-proofing prevents obsolescence. Prioritize cables with higher bandwidth and extra fibers to accommodate growth. This strategy reduces long-term costs, offering a sustainable investment in network infrastructure.

Conclusion

In conclusion, selecting the right fiber optic cable equipment requires careful consideration of factors like fiber type, cable jacket, connectors, and installation requirements. Each decision impacts performance, reliability, and cost-effectiveness. By evaluating your specific needs and future growth potential, you can ensure a robust and efficient telecommunications network. Invest in quality and compatibility to achieve seamless connectivity and long-term success.

Footnotes:

Understanding what constitutes fiber optic cable equipment helps in making informed choices for optimizing performance and reliability. ↩

Insight into the workings of telecommunications networks supports better decision-making in cable equipment selection. ↩

Comprehensive resources on fiber types guide appropriate selection for specific network needs. ↩

Insights on fibers OM1 to OM5 help in selecting appropriate multimode cables for different data rate and distance requirements. ↩

Understanding OS1/OS2 standards aids in choosing suitable cables for long-haul communication applications. ↩

PVC use cases illustrate its suitability for indoor installations due to specific features like flexibility. ↩

PE materials offer insights into choosing outdoor cables capable of withstanding environmental stress. ↩

Resources about various fiber optic cable components aid in ensuring correct specifications for compatibility and performance. ↩

Matching connectors such as LC, SC, and MPO with devices ensures seamless connectivity and reduces installation challenges. ↩

Understanding the applications and benefits of LC connectors provides insights into space-saving and performance advantages. ↩

The push-pull mechanism provides ease of connectivity, explained in SC connector resources. ↩

Selecting the right number of fibers ensures scalability, future-proofing your network infrastructure. ↩