How to Choose Your Fiber Optic Cable?

Engineers and purchasing managers often feel overwhelmed by the complexity of fiber optic cable selection. This confusion leads to suboptimal performance, frequent replacements, and network downtime. By understanding key factors like fiber type, cable jackets, connectors, and environmental conditions, you can choose the right cable the first time.

Selecting the proper fiber optic cable involves evaluating distance, bandwidth, environment, and future needs. Choosing single-mode vs. multimode fibers, the correct jacket material (such as LSZH1), proper connectors like MPO/MTP, and planning for environmental challenges ensures reliable performance. With a careful, informed approach, you’ll secure a durable, high-speed, and future-proof network.

I recall working with a client in the United States who chose the wrong cable type. After their network underperformed, they realized their decision was based solely on price, ignoring critical factors like distance and attenuation. Once we re-evaluated their needs, selected a suitable single-mode fiber, and upgraded connectors to match, their system improved dramatically. Let’s dive deep into the considerations that guide you to the perfect fiber optic cable for your application.

What are the factors to consider when selecting fiber optic cable?

When choosing a fiber optic cable, consider factors like distance requirements, bandwidth needs, environment, connector compatibility, installation conditions, and future scalability. By aligning these aspects with your project’s goals, you’ll ensure not only initial success but also long-term reliability and cost-effectiveness.

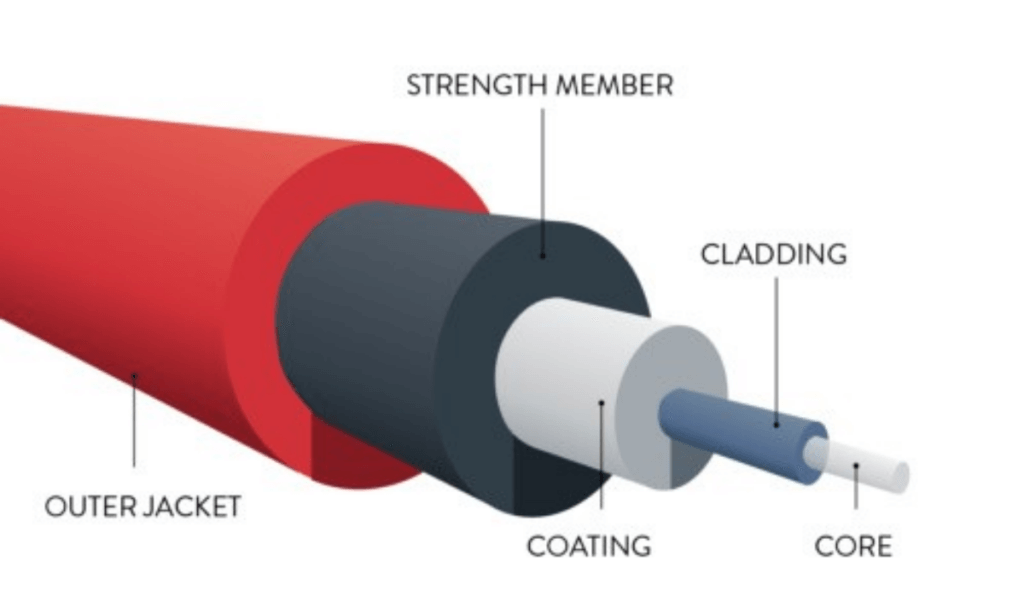

Focus on fiber type (differences explained2), link distance, network speed, environmental conditions, cable jacket materials, connector types, and future-proofing your infrastructure3. Evaluating these parameters guides you toward a cable that maintains low attenuation, supports current and future speeds, and endures in its environment.

What are the key differences between single-mode and multimode fiber optic cables?

Single-mode fibers have a tiny core and support longer distances with higher bandwidths but require more expensive transceivers. Multimode fibers have larger cores, simpler optics, but shorter reach and lower total bandwidth capacity. Choosing correctly depends on distance, budget, and desired data rates.

single-mode vs. multimode differences

Single-mode fiber: small core (~9µm), ideal for long distances and high speeds. Multimode fiber: larger core (50 or 62.5µm), suitable for shorter links. Consider if you need extended reach or just a few hundred meters. For higher data rates over short distances, you might select OM4 fiber4 to handle 10GbE, 40GbE, or 100GbE within a data center.

How do I determine the right cable jacket material for my installation?

Selecting the proper jacket involves understanding environmental demands. PVC, LSZH, and PE each have unique properties. Evaluate fire codes, temperature ranges, chemical exposure, and indoor/outdoor placement. The right jacket optimizes both performance and compliance with building codes5.

For indoor use, LSZH ensures low toxicity in fire. Outdoor installations need PE for moisture and UV resistance. Plenum spaces require OFNP-rated cables. By aligning jacket materials with conditions, you secure a durable and safe cable.

What factors should I consider when choosing fiber optic connectors?

When selecting connectors, factor in compatibility with existing hardware, polarity, fiber count, insertion loss, and mechanical stability. MPO/MTP connectors6 simplify parallel optics deployments, while LC connectors are favored for high-density data centers. Ensure the connector type matches your transceivers and network design.

APC connectors offer low return loss for long-haul or high-speed systems. UPC connectors are simpler and cheaper but might have slightly higher reflection. Evaluate insertion loss specifications and consider endface quality to maintain optimal link budgets.

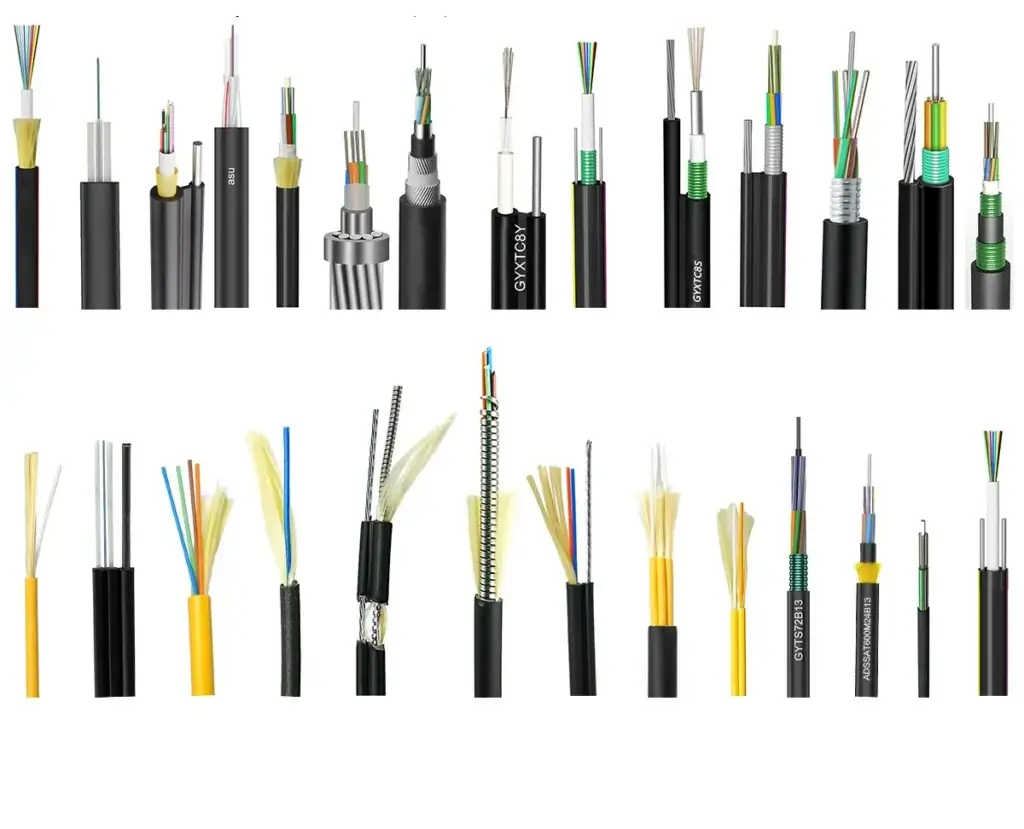

What are the environmental conditions that might impact fiber optic cable selection?

Environmental conditions—temperature extremes, moisture, UV exposure, chemicals, mechanical stress—affect attenuation, longevity, and reliability. Outdoor cables with water-blocking elements, UV-resistant jackets, and rugged armor withstand challenging conditions. Indoor cables in plenum spaces require LSZH jackets for fire safety. Proper installation7 and adherence to local codes ensure stable operation.

In high-temperature or harsh chemical environments, choose specialty cables and coatings. For buried cables, consider rodent-resistant armor. Each condition you anticipate guides you to specific cable constructions, ensuring the fiber’s integrity over time.

Additional Considerations for Choosing Fiber Optic Cable

Beyond fiber type and environment, consider bandwidth and standards (TIA/EIA and ISO/IEC standards), PMD and chromatic dispersion for high speeds, UPC vs. APC polish types, tight-buffered vs. loose-tube constructions, fiber count, cost-benefit analysis, vendor reputation (OEM vs. third-party8), and future expansions.

Opt for higher-grade fibers if you foresee growth. OM4 or single-mode can accommodate future upgrades to 100GbE or beyond. WDM (Wavelength Division Multiplexing9) on single-mode can multiply capacity without new cables. Thorough documentation, labeling, and testing ensure easy maintenance and scalability.

Future-Proofing Your Fiber Optic Infrastructure

The pace of network evolution demands planning ahead. Even if current requirements are modest, anticipating growth saves money and downtime later. For higher speeds, consider OM4/OM5 or single-mode. For scaling capacity, single-mode plus WDM technologies shine.

If you’re currently at 1GbE, selecting a fiber that supports 10GbE or 40GbE ensures smooth upgrades. Designing physical infrastructure (conduits, trays) with spare capacity, modular patch panels, and documented cable routes eases future transitions.

Practical Steps to Select the Right Fiber Optic Cable

- Define distance and bandwidth: e.g., 10GbE over 300m or 100GbE over 10km.

- Choose fiber type: multimode (OM3/OM4/OM5) for shorter runs, single-mode for longer distances.

- Assess environment: indoor, outdoor, harsh conditions—pick jackets and armor accordingly.

- Select connectors: MPO/MTP for parallel optics, LC for density, APC for low reflection.

- Comply with local codes and fire ratings: LSZH vs. PVC, plenum vs. riser.

- Plan for future growth: Consider future-proofing strategies].

- Evaluate vendor reputation and warranties: Compare OEM and third-party].

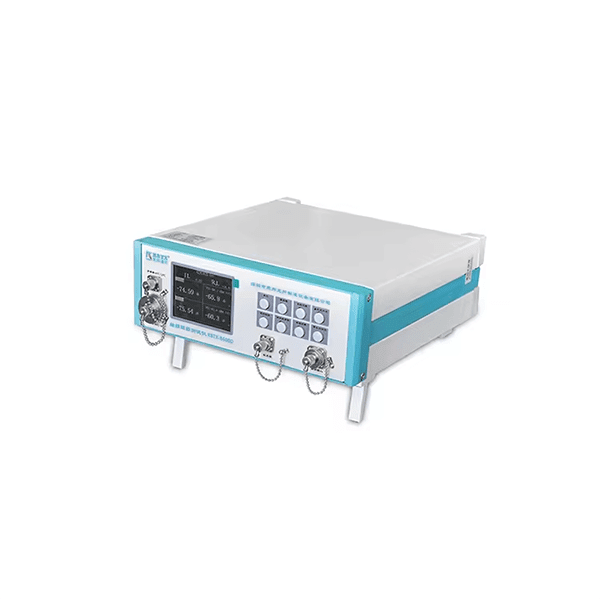

- Test after installation with OTDR and insertion loss measurements.

- Train staff and maintain documentation for swift troubleshooting.

Following this structured approach avoids guesswork and ensures your fiber optic cable investments deliver consistent, high-speed connectivity for years.

Conclusion

Choosing the right fiber optic cable involves balancing multiple factors: fiber type (single-mode vs. multimode), distance, environment, jackets (LSZH compliance), connectors (MPO/MTP standards), and adherence to structured cabling standards10. By evaluating these points, you ensure your chosen cable meets current needs and can adapt to future demands.

At Aimit Communication (Shenzhen) CO., LTD (AIMIFIBER), I, Sophie Wang (sophie@aimifiber.com), can help guide you through these decisions. Whether it’s a small office network or a large-scale data center, a well-chosen cable ensures reliability, performance, and scalability—today and tomorrow.

Explains LSZH cable properties, compliance requirements, and fire safety advantages over PVC and other jackets. ↩

This resource detailing technical distinctions, distance capabilities, and typical applications for single-mode vs. multimode fibers. ↩

Discusses planning for future growth, choosing advanced fiber types, and infrastructure designs for seamless upgrades. ↩

Clarifies OM4’s specifications, bandwidth, and extended reach for higher-speed networks compared to OM3. ↩

Information on building fire codes (NEC, NFPA) and required cable ratings (OFNP, OFNR) for safe indoor installations. ↩

Guidance on MPO/MTP connector standards, polarity management, and recommended practices for high-density parallel optics links. ↩

Offers best practices for cable installation, including pulling tensions, bend radius guidelines, and minimizing signal loss. ↩

Helps compare OEM vs. third-party cable suppliers, focusing on quality, warranties, and vendor reputation for long-term reliability. ↩

Explains how WDM (CWDM/DWDM) can scale single-mode fiber capacity without new fiber deployments. ↩

Details TIA/EIA, ISO/IEC standards for structured cabling, performance requirements, and testing methodologies for fiber networks. ↩