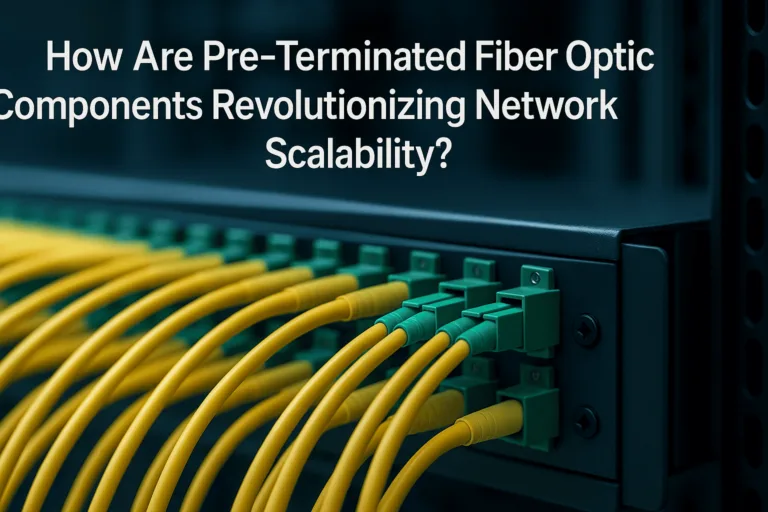

Struggling with slow fiber rollouts and unreliable connections for big projects? On-site termination bogs you down, risks errors, and demands highly skilled (and expensive!) techs. Imagine slashing deployment time; after all, fiber optic cables are essential in modern telecommunications.

Yes, pre-terminated fiber optic cables offer a game-changing solution. (Explore the benefits of pre-terminated fiber). They dramatically speed up high-volume installations, boost reliability by minimizing field errors, and simplify the entire process from planning to plug-in.

I remember one massive data center job years ago. We were weeks behind schedule, and the pressure was immense. Then, we switched to pre-terminated assemblies for a section. The difference was night and day. Let me show you how.

How Do Pre-Terminated Cables Actually Simplify Your Deployment Cycle?

Tired of fiber installation projects dragging on forever? Pre-terminated cables tackle this head-on, turning weeks of work into days. It's a massive time saver, often detailed in discussions around pre-terminated cabling technology and its benefits.

They slash deployment time because connectors are expertly installed and rigorously tested in a controlled factory setting. This means significantly less on-site work and fewer nasty surprises ruining your day.

Let’s dive deeper into this.

Factory Precision: The Standardization Edge

Think about it. In a factory, every termination is done under ideal conditions. Consistent pressure, an ultra-clean environment, and specialized machinery. This isn't just about speed; it's about quality. You get standardized, high-performance connectors every single time. We're talking about a level of precision that’s incredibly tough to replicate in the field, especially when you’re battling dust and tight spaces. This was a huge factor for us on that data center build; the consistency was a lifesaver. Ensuring effective fiber optic cable installation is paramount for such projects.

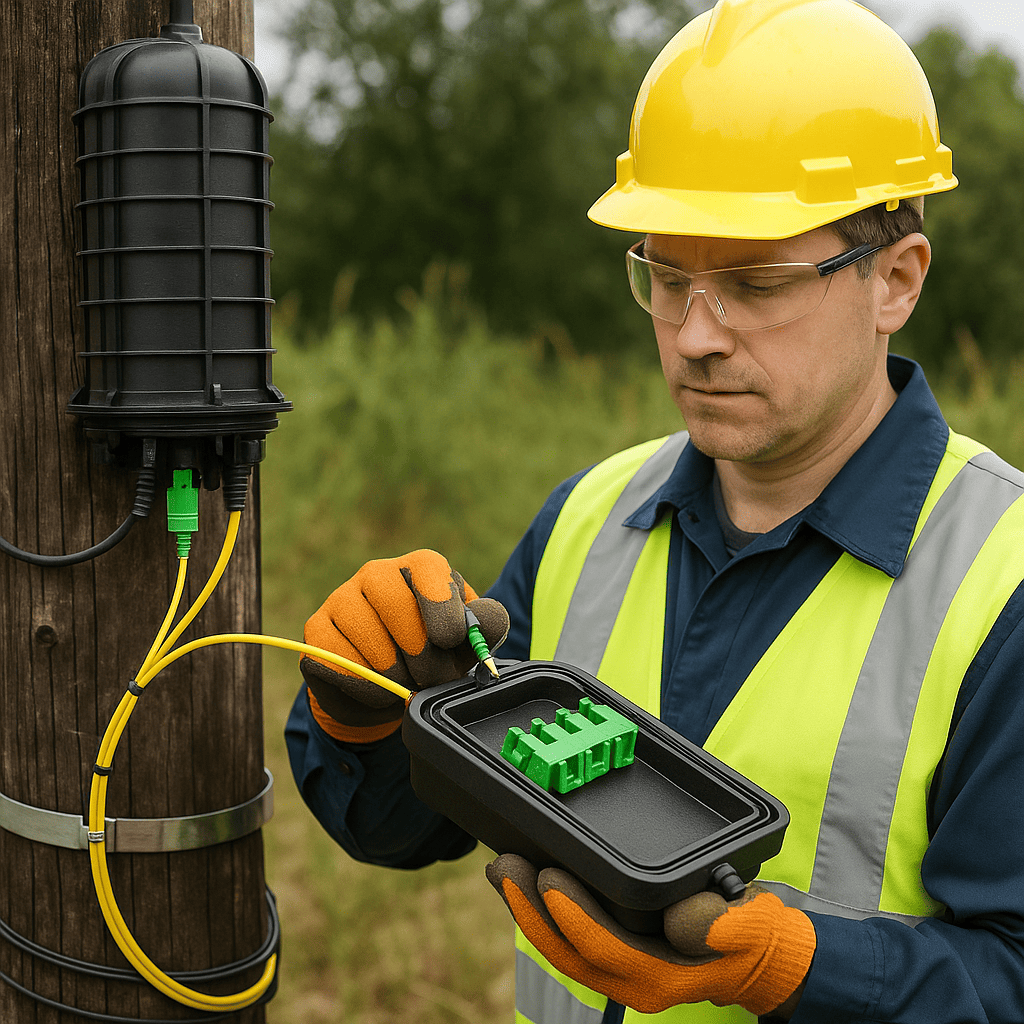

Slashing On-Site Time and Costs

One of the biggest drains on any fiber project is the on-site termination process. You need specialized tool kits, polishers, cleavers, and testers. And let's not forget the consumables. With pre-terminated cables, a huge chunk of that disappears.

I ran the numbers on one of our larger projects. By switching to pre-terminated, we cut our consumables budget by nearly 50%! Plus, our technicians spent less time terminating and more time connecting and testing the actual links. This directly translates to lower labor costs and faster project completion.

Real-World Speed: A Quick Comparison

The difference in speed isn't trivial. It's often dramatic.

| Scenario | Traditional On-Site Termination | Pre-Terminated Solution |

|---|---|---|

| Investment Bank Data Center | Complex cabinet wiring took several weeks | Multi-channel MPO assemblies deployed in days |

| New Campus Network Backbone | Phased termination over 1-2 months | Main runs installed and active in under a week |

This isn't just a marginal improvement; for projects with tight deadlines, this is a total game-changer.

Can Pre-Terminated Solutions Really Minimize Splice Point Risks and Boost Network Reliability?

Worried about those pesky signal losses and potential network failures from too many field splices or poorly made connectors? This is a common, and very valid, fear in our industry, but pre-terminated fiber solutions increase reliability.

Absolutely. Factory-terminated connectors mean fewer, higher-quality connections. This significantly reduces signal loss, drastically lowers failure rates, and ensures cleaner, more robust pathways for your critical data.

Here’s the nitty-gritty.

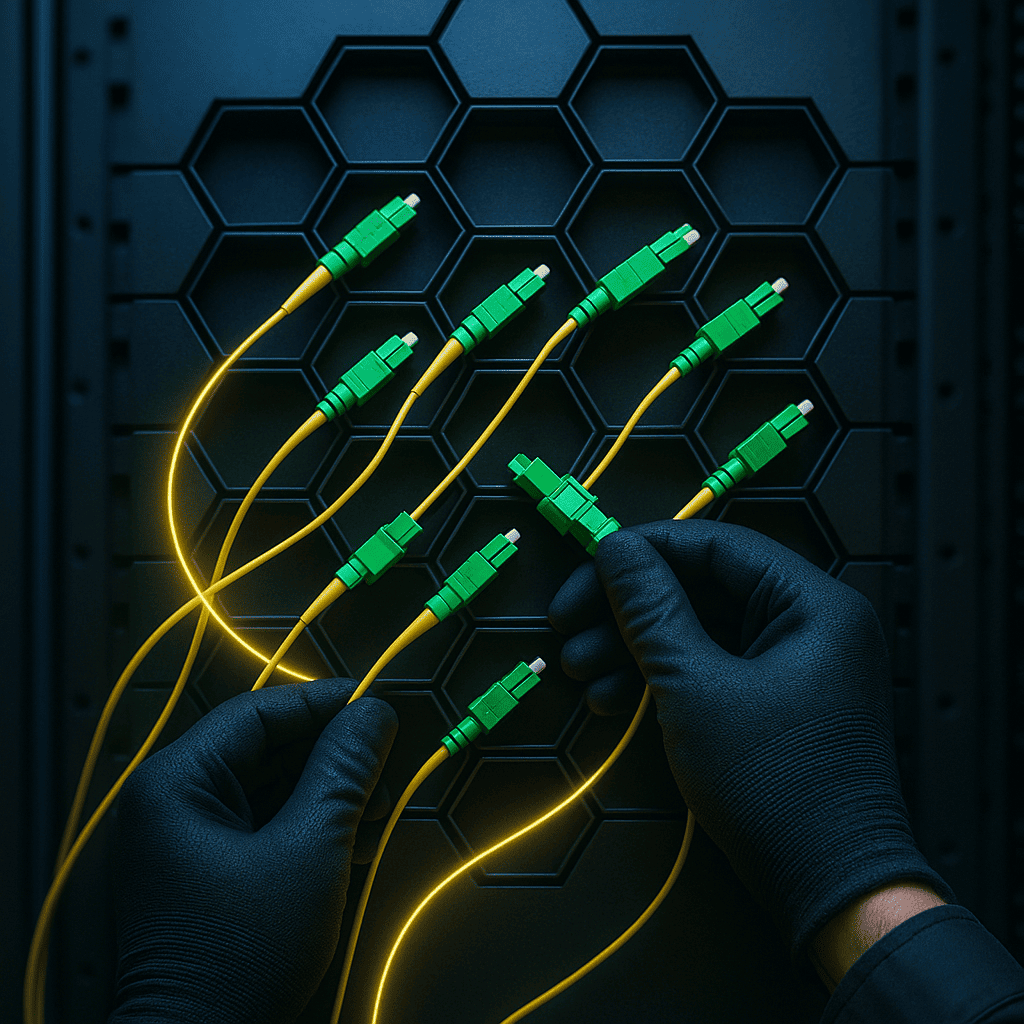

Optimized Connection Loss Through Precision Polishing

Factories use automated polishing machines that achieve an incredible level of precision. This results in connectors with consistently low insertion loss and high return loss (often ≥50dB, sometimes even better for APC connectors). For example, many pre-terminated single-mode patch cords boast typical insertion loss of less than 0.25dB. Trying to hit that consistently in the field, across hundreds or thousands of terminations? It's a tall order. The goal is always to achieve ultra-low loss in fiber optic cable design. I've seen too many networks suffer from "death by a thousand cuts" – tiny amounts of excess loss on many field connectors adding up to big problems.

Drastically Lowering Failure Rates

Every single pre-terminated connector is typically inspected and tested (often with an interferometer for end-face geometry and via light source/power FTeeter for loss) before it leaves the factory. This pre-testing catches defects that might otherwise go unnoticed until much later, causing intermittent issues or outright failures. For critical infrastructure like hospitals, financial institutions, or emergency services, this upfront quality assurance is non-negotiable. It reduces the probability of network interruptions significantly.

Keeping It Clean: The Contamination Factor

Fiber optic connections are incredibly sensitive to contamination. Dust, oils from skin, or other microscopic debris on a connector end-face can cripple performance. Factories maintain clean-room environments for termination. This minimizes the risk of contamination being sealed into the connector. While field cleaning is essential, starting with a perfectly clean, factory-terminated connector gives you a massive head start on reliability.

Final thoughts

Pre-terminated fiber is key for fast, reliable high-volume installs. Prioritize it for new builds; consider hybrid approaches for complex expansions. It's truly the future of efficient fiber deployment. For more insights, visit our fiber optics blog.