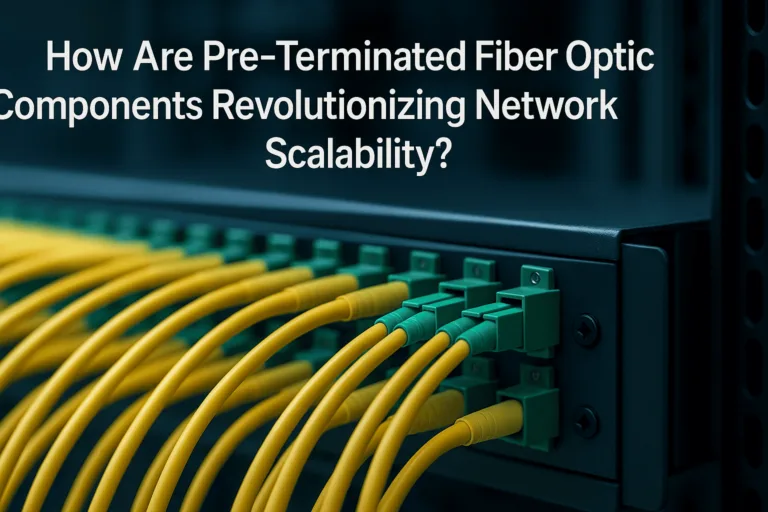

Telecom networks are expanding incredibly fast, highlighting why fiber optic cables are essential in modern telecommunications, but deploying them traditionally can be slow and complex. This often leads to frustrating project delays and increased costs, impacting your bottom line, issues particularly pressing as the last-mile fiber optic cable market sees explosive growth. But what if pre-terminated assemblies, guided by clear standards, could significantly change that for the better?

Standardizing pre-terminated fiber optic assemblies drastically cuts installation time and reduces errors. It ensures that all components work together seamlessly from the start, speeding up project completion and boosting overall network reliability for your clients.

I've seen firsthand how a well-thought-out, standardized approach can transform a challenging installation into a smooth process. Imagine finishing projects 50-70% faster – it’s achievable! Let's explore how this works.

What is the Framework for Standardizing Fiber Optic Pre-terminated Components?

Understanding the framework for standardization is the first step. These aren't just arbitrary rules; they are carefully developed guidelines that ensure everything fits and performs perfectly, right out of the box.

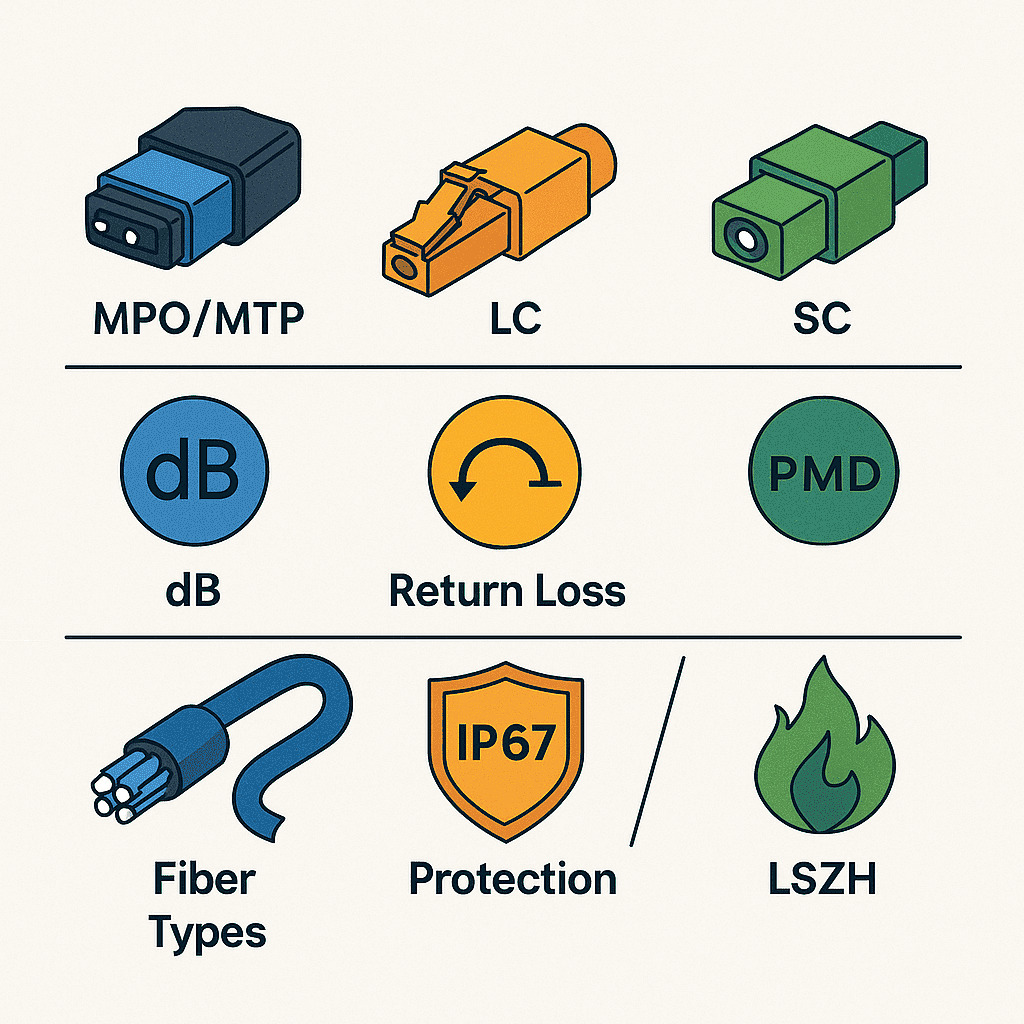

This framework covers core specifications for various types of fiber cables and connectors like MPO/MTP, common optical interfaces such as LC/SC, and pre-polished pigtails. It also includes crucial compatibility tests for performance metrics like insertion loss (IL) and return loss (RL).

At AIMIFIBER, we pay close attention to these standards because they are fundamental to delivering reliable solutions.

Dive Deeper: Core Specifications and Layers

When we talk about standards, we're looking at several layers:

- Key Connector and Interface Standards:

- Connectors: MPO/MTP (Multi-fiber Push On/Pull Off) for high-density applications, and single-fiber connectors like LC (Lucent Connector) and SC (Subscriber Connector) are central. Standards define their physical dimensions, mating durability, and performance.

- Pigtails: Pre-terminated pigtails must adhere to specific polish types (UPC/APC) and fiber type compatibility.

- Performance Testing Standards:

- Insertion Loss (IL): Standards like those from the IEC (International Electrotechnical Commission) or TIA (Telecommunications Industry Association) specify maximum allowable IL. For example, a typical IL for a mated connector pair might be ≤ 0.3dB.

- Return Loss (RL): High return loss is critical, especially for analog or high-speed digital signals. Standards dictate minimum RL values (e.g., >50dB for APC, >35dB for UPC).

- Polarization Mode Dispersion (PMD): For long-haul and high-bit-rate systems, PMD limits are crucial.

Dive Deeper: Technical Specification Layers

The technical specifications can be broken down further:

Physical Layer: This involves:

Fiber Material: Standards like ITU-T G.652.D for standard single-mode fiber or G.657.A/B for bend-insensitive fibers are commonly referenced.

Cable Sheath: Materials like LSZH (Low Smoke Zero Halogen) for indoor safety or robust PVC/PE for outdoor use.

Environmental Performance: Ingress Protection ratings like IP67/IP68 define resistance to dust and water, critical for outdoor or industrial deployments. I've seen requests for IP68 increase for FTTA projects, especially in harsh climates.

Signal Transmission Layer: This considers:

Wavelength Compatibility: For systems using Wavelength Division Multiplexing (WDM), whether it's CWDM (Coarse WDM) or DWDM (Dense WDM), components must support the specific wavelength plans (e.g., ITU-T G.694.1 for DWDM, G.694.2 for CWDM).

Power Handling: For amplified systems using EDFAs (Erbium-Doped Fiber Amplifiers) or Raman Amplifiers, components must handle higher optical powers without degradation. The Optical Fiber Amplifier Market Outlook 2025-2030 indicates continued innovation in this area.

Dive Deeper: Cross-Supply Chain Compatibility

To ensure everything works together, even with parts from different vendors (though I always recommend finding a reliable one-stop supplier like AIMIFIBER!):

- Modular Design: Compatibility with standard enclosures, such as 19-inch racks and ODFs (Optical Distribution Frames), is essential. Adapter types and panel cutouts must align.

- Labeling and Tracking: While not always strictly standardized globally, common practices involve clear port labeling. Some advanced systems use QR codes or RFID for asset management, though universal adoption varies. Clear, consistent labeling is something my client Bayan, a technical project manager, always emphasizes for easy maintenance.

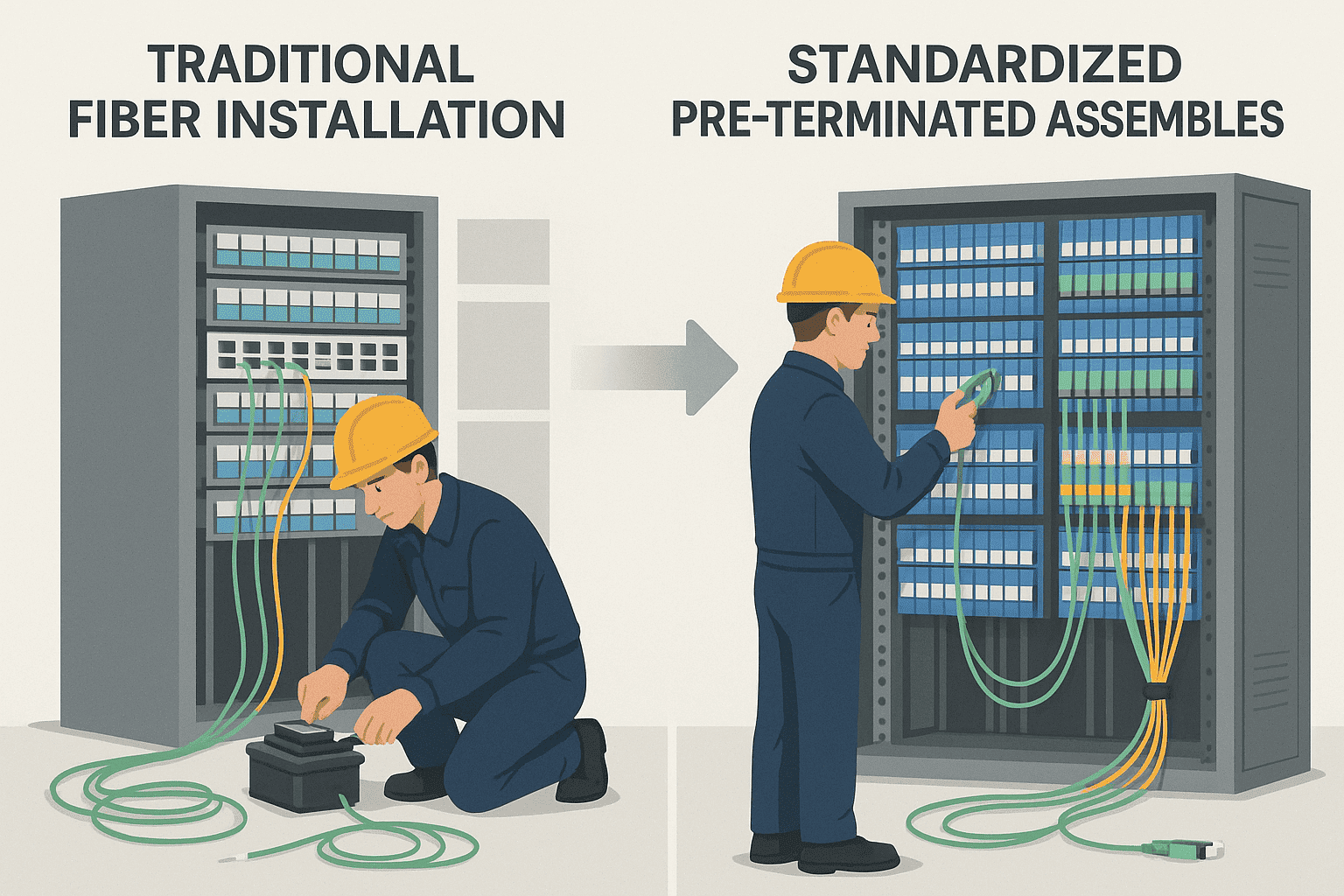

What Are the Technical Advantages of Using Standardized Pre-terminated Components?

The real magic of standardization appears when you look at the technical advantages. It’s not just about compliance; it’s about leveraging the key technologies and standards for fiber optic cable installations to make your projects faster, easier, and more reliable from day one.

Standardized pre-terminated components significantly reduce on-site man-hours through factory pre-configuration and testing. They also simplify complex cabling routes and make project acceptance quicker and far more straightforward due to predictable quality.

I've seen teams go from days of intricate field termination to mere hours of plug-and-play installation.

Dive Deeper: Optimizing Man-Hours

One of the biggest wins is time savings:

- Factory Pre-configuration: Assemblies like MPO/MTP trunks arrive with connectors already attached, polished, and initially tested. This eliminates the need for specialized field termination tools and skills for these complex connectors.

- Reduced On-Site Testing: While final link testing is still needed, the component-level testing done in the factory (like individual patch cord IL/RL) drastically reduces troubleshooting time.

- Rapid Deployment Connectors: Pre-terminated cables with quick connectors (like hardened SC/APC for FTTH drops) mean technicians can connect subscribers much faster, without extensive splicing. This is a boon for annual FTTH rollout contracts like Fernando in Spain handles.

Dive Deeper: Reducing Cabling Complexity

Standardization simplifies the physical layout:

- High-Density Connections: MPO/MTP connectors allow for very dense fiber connections. A single MPO connector can handle 12, 24, or even more fibers, massively reducing the number of individual cables and connectors compared to using duplex LC cables for the same capacity. Think about deploying 40G/100G/400G data center links. This means you can pack more capacity into the same rack space.

- Simplified Cable Management: With fewer individual cables and predictable lengths, cable routing becomes neater and easier to manage in pathways, cabinets, and enclosures. This reduces the risk of damage from tangled or stressed cables.

- Consistent Polarity: Standards define MPO polarity methods (Type A, B, C). Knowing the assembly follows a specific polarity standard ensures transmit and receive paths are correctly aligned without guesswork.

Dive Deeper: Revolutionizing the Acceptance Process

This is where hybridization really shines for project managers:

Quality Assurance Shifted to Factory: Each pre-terminated assembly can come with a factory test report (e.g., OTDR trace, IL/RL values for each fiber). This provides a baseline quality assurance before the components even reach the site. Test Parameter Typical Standardized Value Benefit for Acceptance Connector IL (MPO) ≤ 0.35dB (Elite) Predictable link budget Connector RL (APC) > 60dB Minimizes signal reflection End-face Geometry IEC 61300-3-35 compliance Ensures proper physical contact - Reduced Commissioning Faults: Because components are made to consistent standards and pre-tested, the number of faults found during commissioning (like high loss, bad splices, or dirty connectors) is significantly lower. This means faster sign-off. Fernando, who has high quality demands for Telefonica projects, would value this predictability.

- Easier Troubleshooting: If a problem does occur, standardized components make it easier to isolate the issue. Swapping out a pre-terminated patch cord or cassette is much simpler than re-terminating a field-installed connector.

Final thoughts

Standardizing pre-terminated fiber optic assemblies clearly boosts efficiency. It helps you hit those critical speed and quality targets, whether in data centers or remote FTTA sites. This approach is key to successfully installing and maintaining a fiber optic cable system for the long term, paving the way for a more modular and automated future.