What Are the Key Technologies and Standards for Fiber Optic Cable Installations?

In the rapidly evolving telecommunications industry, ensuring efficient and reliable fiber optic connections[^1] is paramount. However, the complexity of fiber optic technologies and installation standards can be daunting. Understanding these critical components is essential to achieving seamless operations.

The key technologies and standards for fiber optic cable installations include understanding cable types, connection technologies, installation guidelines, and adherence to specific standards like NECA/FOA 301[^2]. By mastering these elements, telecom professionals can ensure efficient and reliable fiber optic networks.

Imagine embarking on a journey through the intricate pathways of fiber optic technology, where each connection and cable serves as a vital link in the vast network of telecommunications. This blog post will unravel the complexities of fiber optic cable installations, offering insights into the essential technologies and standards that ensure optimal performance.

How Do Fiber Optic Cable Types and Characteristics Influence Installations?

To effectively install fiber optic cables, it's crucial to first understand the different types of cables and their characteristics. Fiber optic cables are primarily categorized into single-mode[^3] and multi-mode fibers[^4]. Each type has distinct applications, influencing installation strategies.

Single-mode fibers are used for long-distance data transmission, providing higher bandwidth. Multi-mode fibers, with larger core diameters, are ideal for short-distance data transmission. Understanding these characteristics helps telecom engineers choose the right cable for specific applications.

Single-mode Fibers

Single-mode fibers have a small core diameter, typically around 9 micrometers, allowing only one mode of light to propagate. This reduces signal attenuation and increases bandwidth, making them suitable for long-distance communication.

Multi-mode Fibers

Multi-mode fibers have larger core diameters, generally 50 or 62.5 micrometers, supporting multiple modes of light. They are cost-effective for short-distance communication but have higher signal attenuation compared to single-mode fibers.

Comparison Table: Single-mode vs. Multi-mode Fibers

| Feature | Single-mode Fiber | Multi-mode Fiber |

|---|---|---|

| Core Diameter | ~9 micrometers | 50-62.5 micrometers |

| Signal Attenuation | Low | High |

| Distance Suitability | Long | Short |

| Cost | Higher | Lower |

What Connection Technologies Are Essential for Fiber Optic Installations?

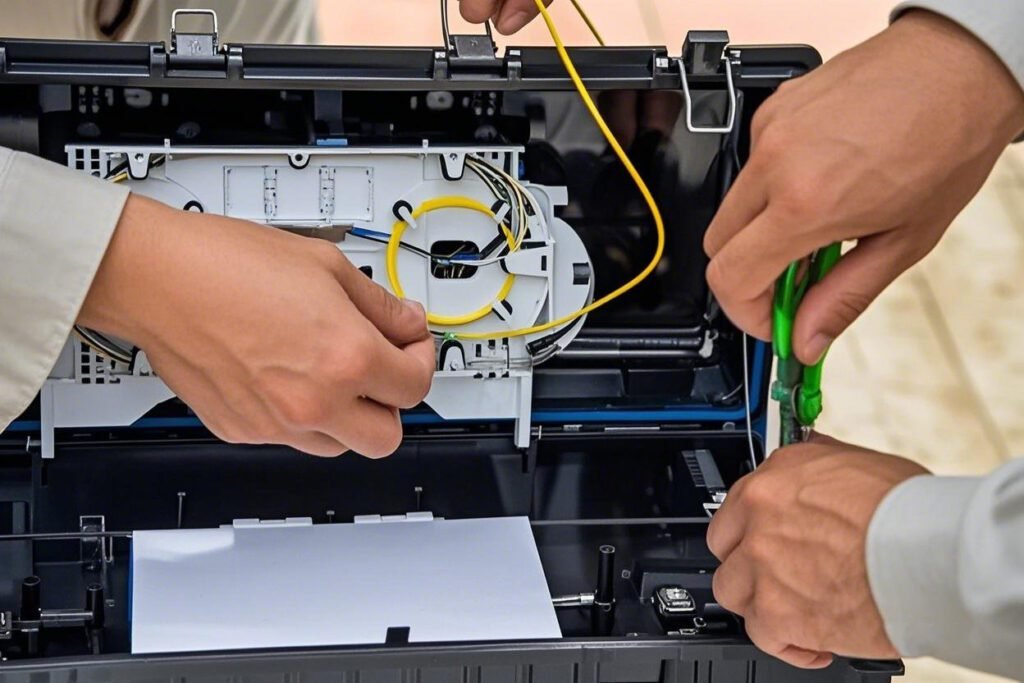

Fiber optic connections are pivotal for linking cables, and understanding the various connection technologies[^5] is essential for efficient installations. These include connectors, splicing, and termination techniques.

Essential connection technologies for fiber optic installations include connectors[^6] such as ST, SC, and LC, as well as splicing and termination methods. These technologies ensure reliable connections and facilitate easy maintenance and upgrades.

Fiber Optic Connectors

Connectors are used to join fiber optic cables and facilitate easy connection and disconnection. Some popular types include:

- ST Connector (ST): Features a bayonet-style coupling, suitable for long-distance applications.

- Standard Connector (SC): Push-pull design with high precision, ideal for data communication.

- Lucent Connector (LC): Smaller size, used in high-density applications.

Splicing and Termination

Splicing and termination are critical for joining fiber optic cables:

- Splicing: Involves precise alignment of the fiber cores for minimal signal loss.

- Termination by Connectors: Uses connectors for easy disconnection and reconnection, essential for maintenance.

How Do Installation Guidelines and Best Practices Ensure Efficient Operations?

Adhering to installation guidelines and best practices[^7] is crucial for efficient and reliable fiber optic operations. These practices include planning, handling cables, and using appropriate installation techniques.

Effective installation guidelines include detailed planning, proper cable handling, and techniques like pulling and blowing. These best practices minimize installation errors and ensure the longevity of fiber optic networks.

General Installation Practices

- Planning: Develop a detailed installation plan, including equipment specifications and testing requirements.

- Handling Cables: Avoid pulling on the fiber itself and adhere to the maximum pulling load rating to prevent damage.

Installation Techniques

- Pulling and Blowing: Use swivels and lubricants for pulling, and pressurized systems for blowing to reduce tension on cables.

- Trenching and Conduit Placement: Install cables underground in conduits, considering local conditions for depth placement.

What Are the Specific Installation Standards for Fiber Optic Cables?

Compliance with specific installation standards is essential for ensuring safety and reliability in fiber optic operations. The NECA/FOA 301 standard[^8] outlines comprehensive guidelines for such installations.

The NECA/FOA 301 standard provides guidelines for fiber optic installations, covering support structures, cable types, termination, and testing. Adhering to these standards ensures high-quality, compliant installations.

NECA/FOA 301 Standard

This standard provides detailed guidelines for installing and testing fiber optic cables:

- General Guidelines: Address support structures, cable removal, and grounding.

- Cable Types and Installation: Focus on flammability ratings and color codes.

- Termination and Testing: Cover connector use, splicing, and testing methods like OTDR[^9].

Conclusion

In the world of telecommunications, mastering the technologies and standards of fiber optic cable installations is vital. From understanding cable types and connection technologies to adhering to installation guidelines and standards like NECA/FOA 301, telecom engineers can ensure efficient and reliable network operations. By following these best practices, professionals can address the complexities of fiber optic installations, paving the way for seamless communication and connectivity.

Understanding and implementing these elements will not only enhance the quality and reliability of fiber optic networks but also ensure compliance with industry standards, ultimately leading to successful telecommunications projects.

[1]:Explains why fiber optic connections are critical to telecommunications, providing high-speed and reliable data transfer, supporting efficient network functioning.

[2]:Guides in ensuring installations are safe, compliant, and adhere to the industry-best practices, which are essential for maintaining network reliability.

[3]:Details about single-mode fibers that explain why they are suitable for long-distance communication, helping engineers select the appropriate cable type.

[4]:Provides information on multi-mode fibers and applications, driving informed decisions on cable selection for short-distance network installations.

[5]:Enumeration of technologies that ensure strong connectivity, addressing maintenance and upgrade needs within high-performing fiber optic networks effectively.

[6]:Overview of fiber optic connector types, assisting in the correct equipment selection for specific network requirements.

[7]:Outlines best practices in installation, ensuring minimal error rates and sustained network performance leading to long-term connectivity solutions.

[8]:Ensures installations meet particular safety guidelines, crucial for industry compliance and avoiding service interruptions.

[9]:Offers insight into OTDR usage in testing fiber optic installations, ensuring signal strength and integrity over network connections.