Who are the Best Custom Fiber Optic Cable Suppliers in the Industry?

In the fast-paced world of telecommunications, I know that finding a reliable supplier for custom fiber optic cables can be challenging. I have faced these concerns when I have worked on data center and FTTA projects for various clients. I remember searching far and wide for consistent product quality and stable lead times. Mismatched or subpar cables can lead to inefficiencies and added costs. I have seen this happen more than once on projects where mismatched connectors slowed down the installation. But there are excellent suppliers ready to meet your needs with precision and innovation.

The best custom fiber optic cable suppliers are Infinite Cables1, OFS Optics2, Thorlabs3, Opticonx4, American Wire Group5, and Cability, Inc.6. They offer specialized solutions tailored to various industries, ensuring high quality and customization to meet specific client needs.

I have managed large-scale telecommunications projects where seamless connectivity was crucial for success. The right cable choice made a difference. The success of these projects often hinged on consistent cable performance. Selecting the right supplier helped transform potential challenges into opportunities for excellence, especially in data center expansions and FTTA deployments.

What Makes Infinite Cables a Top Choice for Custom Fiber Optic Assemblies?

Infinite Cables is a standout in the realm of custom fiber optic assemblies. They offer a range of products. These include duplex fiber patch cords, breakout/fanout fiber cables, fiber optic pigtails, and armored fiber optic cables.

Infinite Cables excels with a vast array of custom fiber optic assemblies7. They use advanced equipment to manufacture cables with various fiber types and connectors. Their expertise ensures high-quality solutions for any project.

I have reviewed their solutions. Their state-of-the-art equipment creates cables with different fiber types such as OM1, OM2, OM3, OM48 and singlemode fibers. They also offer a variety of connectors, including LC, SC, ST, and MTP/MPO[^11]. This versatility is vital. In some of my data center deployments, the density of fiber connections was overwhelming. MTP/MPO trunk cables simplified that complexity. Infinite Cables also provides good technical support. They can help you decide on the right fiber type if you are uncertain about link distances or bandwidth requirements.

My Personal Story with Infinite Cables

I recall a time when a project required very short lead times. The construction schedule for a large data center demanded 5000 breakout cables with MTP connectors. I only had a two-week window. I approached Infinite Cables. I explained the tight schedule. They promised to expedite production. They delivered on time. My client was satisfied. I remember feeling a sense of relief when I saw the neatly labeled boxes arrive. The labeling was clear, and the quality was consistent from cable to cable.

Technical Considerations for Infinite Cables

Many of my colleagues often ask how to evaluate custom cable providers. I encourage them to look at a table of product specs versus project requirements. Here is a simple example:

| Aspect | Project Requirement | Infinite Cables' Offering |

|---|---|---|

| Fiber Type | Singlemode (G.657.A2) | G.657.A2, G.652.D, OM3, OM4, etc. |

| Connector Type | MTP and LC | MTP/MPO, LC, SC, ST, FC |

| Cable Jacket Rating | LSZH/ OFNR | LSZH, OFNR, OFNP |

| Pulling Grip (if required) | Yes | Available |

| Pre-Termination Testing Report | Needed for all assemblies | Provided with each custom assembly |

I have used a similar checklist to ensure that the project specs matched the supplier’s capabilities. Infinite Cables impressed me with thorough documentation. They also offered suitable packaging options like reels or spools.

Why Choose OFS Optics for Specialty Optical Fiber Solutions?

OFS Optics is well-known for custom and specialty optical fiber solutions. They serve many industries, including medical and aerospace. This is possible through advanced coatings and materials that withstand harsh conditions.

OFS Optics is ideal for industries requiring specialty fibers. They offer application-specific solutions with advanced coatings to handle harsh environments. This helps guarantee durability and performance.

The company provides polarization-maintaining fibers[^12], high-power laser transmission fibers, and composite cables that combine optical fiber with copper wire. This level of specialization stands out. I remember an aerospace project where cables needed to handle extreme temperature shifts. OFS Optics offered a solution with special polymer coatings. They also integrated copper conductors for powering small sensors along the cable run. This saved installation costs by reducing the number of separate cables.

Table of OFS Optics Key Products

Here is a quick reference table. It reflects some of their specialized lines:

| Product Type | Key Feature | Typical Application |

|---|---|---|

| Polarization-Maintaining | Maintains signal polarization | Aerospace, Defense, Sensor Systems |

| High-Power Laser Transmission | Withstands high-energy signals | Industrial Lasers, Medical Lasers |

| Composite Cables | Hybrid design | Harsh Environment Installations |

| Specialty Coatings | Enhanced temperature tolerance | Aerospace, Oil & Gas Environments |

I have seen engineers in FTTA installations explore such cables because they need protective coatings for exposed weather conditions. OFS Optics can address these specialized requests. Their solutions give you peace of mind in harsh conditions. This is especially true if you are working in remote cell tower sites where temperature swings are common.

How Does Thorlabs Provide Efficient Custom Fiber Optic Solutions?

Thorlabs is known for its efficient custom fiber optic patch cable services. They have a wide selection of fibers and fast turnaround times.

Thorlabs offers quick custom solutions with many fiber types and connectors. They ensure fast delivery. They also support OEM needs. This makes them a top choice for time-sensitive projects.

Thorlabs supports single mode, multimode, polarization-maintaining, and doped fibers. They offer connectors like FC/PC, ST, LC, and even different jacket colors. If you need quick prototypes, Thorlabs can expedite production. I remember assisting a research lab that needed specialized fiber assemblies in less than a week. Thorlabs was one of the few that could deliver on that timeline. Their ability to handle small orders is also a plus. Other suppliers sometimes have higher minimum order quantities.

My Quick Turnaround Experience

I once collaborated with a small R&D group that tested new sensor arrays. They had strict deadlines. They needed just 20 custom patch cords, each with a unique length and color-coded jackets. Thorlabs offered me the shortest possible lead time. The project manager was happy. The testing began on schedule. From my vantage point, such rapid response is priceless when time is tight.

Thorlabs vs. Other Suppliers (Comparison Table)

I compare Thorlabs to other suppliers when speed matters. I created a table that outlines typical lead times and minimum order quantities:

| Supplier | Average Lead Time for Custom Orders | Minimum Order Quantity | Cost Range per Cable (Est.) |

|---|---|---|---|

| Thorlabs | 3-7 days | No strict minimum | Medium |

| Supplier A | 2-4 weeks | 50 pieces | Low |

| Supplier B | 1-2 weeks | 10 pieces | Medium-High |

| Supplier C | 2-3 weeks | 20 pieces | Medium |

Note: These figures are approximate. They come from my personal experiences and communications with various vendors. Thorlabs’ edge often lies in the ability to ship smaller quantities quickly.

What Sets Opticonx Apart in the Fiber Optic Cable Manufacturing Industry?

Opticonx specializes in high-quality fiber optic interconnect and trunk cables. They offer custom solutions for data centers and network installers.

I have used Opticonx cables for big data center expansions. They focus heavily on trunk cables, which often come with MTP or MPO connectors. They supply high-fiber-count cables that simplify high-density patching. If you plan massive expansions, you might consider trunk solutions that reduce clutter.

Opticonx stands out for trunk cable quality. They design cables that handle high-density demands in data centers. They help with long runs between server racks and distribution areas. My personal experience with them has been positive. Their cables typically come with robust strain relief. They label each cable end well, which reduces confusion during installation.

Opticonx also invests in rigorous testing. They often provide insertion loss and return loss reports for each trunk assembly. They offer advanced protective features for cables that might be pulled through conduits or cable trays. I have worked on a project where the cables needed to run through narrow overhead trays in a data center. Opticonx recommended a smaller cable diameter that still housed 24 fibers. This minimized space usage and helped keep the installation clean.

A Table of Opticonx Key Focus Areas

| Focus Area | Relevance in Projects | Additional Note |

|---|---|---|

| Trunk Cable Assemblies | Data Center & High Fiber Counts | MTP/MPO up to 72 or more fibers |

| Pre-Terminated Solutions | Speed of Deployment | Saves splicing time on-site |

| Custom Fiber Counts | Flexibility | 12, 24, 48, 72, or higher fiber counts |

| Low-Loss Connectors | Critical for 40G/100G systems | Ensures minimal signal degradation |

I appreciated their customization approach. In some places, we needed non-standard cable lengths of 37 meters or 103 meters. They delivered precisely that. They also understood the shipping constraints for overseas deliveries, which was helpful for an installation in Europe.

Why Consider American Wire Group for Custom Fiber Solutions?

American Wire Group manufactures standard and custom fiber optic cables. They aim for high-quality products tailored to your needs.

I often see them in projects that merge fiber optic requirements with electrical infrastructure. They handle big construction jobs, wind farms, and large telecommunication expansions. They offer a broad product line. This includes fiber cables that are robust and intended for harsh outdoor conditions.

American Wire Group is a reliable source if you need an all-in-one solution. They are known for wide inventory and consistent shipping times. They can provide custom fiber cables along with other wiring solutions. I have found them especially helpful when I needed a single supplier to handle multiple cable types for large-scale installations.

They can incorporate various jackets, armoring options, or even special rodent-resistant elements. I once encountered a project in a rural area prone to rodent damage. My client’s cables were at risk. American Wire Group’s armoring solutions reduced that risk. Their engineering team guided me on which designs best handled rodent interference.

Typical American Wire Group Cable Features

| Feature | Benefit | Typical Application |

|---|---|---|

| Rodent-Resistant Armor | Prevents cable damage | Rural and Outdoor Deployments |

| UV-Stabilized Jackets | Long lifespan under sunlight | Aerial or Outdoor Installations |

| Gel-Filled Tubes | Water-blocking and stable signal | Underground or Buried Networks |

| Composite Cables | Consolidates data and power | Industrial or FTTA Sites |

These solutions can boost your network reliability. American Wire Group also addresses weather concerns. If your area has heavy rainfall or strong winds, you can explore their ADSS or figure-8 cables.

What Makes Cability, Inc. a Versatile Supplier for Custom Cables?

Cability, Inc.offers prototypes and production runs of custom cables with fiber optic connectors. They cater to specific client specifications.

I have noticed that some suppliers impose large minimum orders. But Cability, Inc. is flexible in that regard. They can handle small pilot projects or large volumes. This versatility is useful. In my experience, small pilot projects often test new products or new layout concepts. Once tests pass, the project scales. If you want to keep the same supplier, Cability, Inc. can ramp up production.

Cability, Inc. stands out for its adaptability. They work well with smaller, specialized requests. They are also open to large production runs. This helps you stay consistent with the same supplier throughout the entire project life cycle.

They have a broad range of connector options. This includes LC, SC, FC, ST, and MTP. If you need mechanical protection, they offer robust jackets or even stainless-steel armoring. Once, I needed a cable for an outdoor event. The cables ran across the ground, where foot traffic was heavy. We used a rugged, tactical-grade solution from Cability, Inc. The cables survived the event with minimal wear.

Cability, Inc. Prototyping Table

| Stage | Description | Benefit |

|---|---|---|

| Requirement | Gather design specs: length, connectors, jacket type | Clear scope, easy adjustments |

| Prototype | Build a small batch of custom assemblies | Test performance before scaling |

| Feedback | Check insertion loss, mechanical durability | Ensure design meets actual needs |

| Production | Ramp up to full volume if prototype is approved | Maintain consistency in large runs |

I found this approach ideal. It allows me to test cable performance under real conditions. If changes are needed, it is easier to adjust in the prototyping phase. For instance, if the strain relief is insufficient, we can fix that before large-scale production.

My Experience with AIMIFIBER as a Manufacturer and Supplier

I am Sophie Wang. I work at Aimit Communication (Shenzhen) CO., LTD under the brand name AIMIFIBER. We offer a large variety of fiber optic cables and assemblies. We have 16 production lines, 380 workers, and we handle B2B OEM/ODM requests. We have produced many customized solutions for data centers, FTTA installations, and other telecom scenarios. Sometimes, prospective customers wonder how we compare to the established brands mentioned above. I believe we stand out due to our comprehensive product range and our dedication to quality.

AIMIFIBER’s Custom Cable Focus

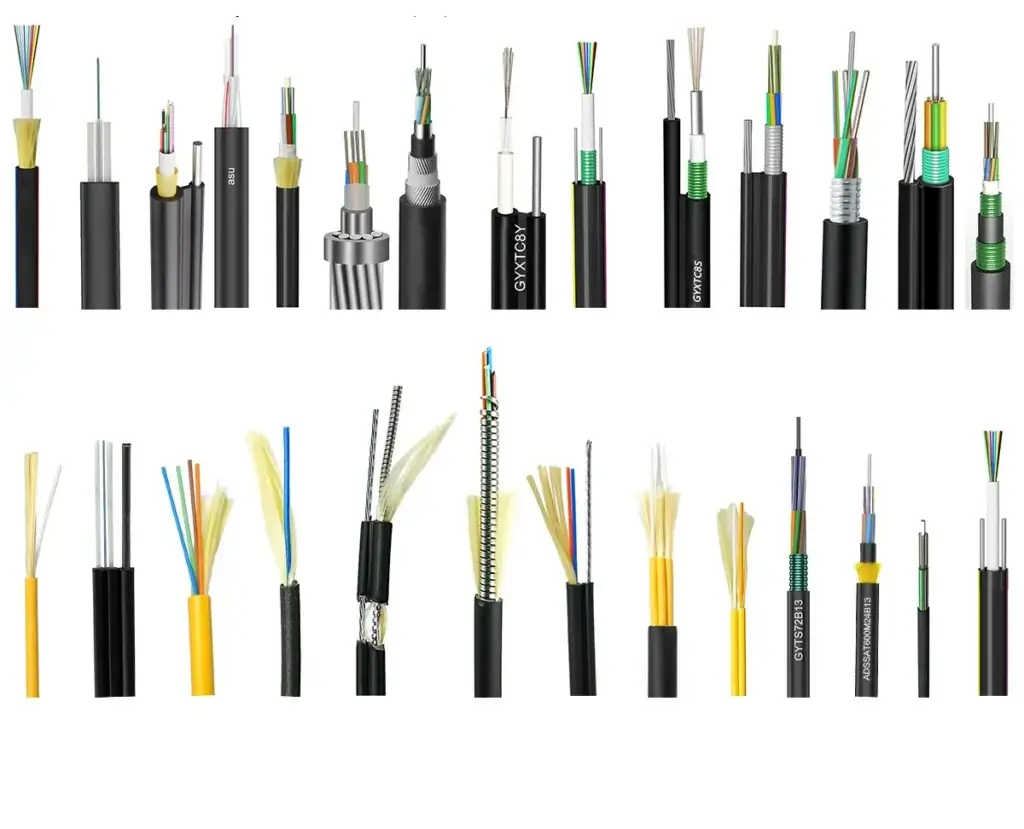

We handle various categories:

- Outdoor Fiber Optic Cable: Armored, ADSS, figure-8, hybrid, direct burial, duct, air-blown.

- Indoor Fiber Optic Cable: FTTH drop cable, breakout cable, indoor armored cable, pre-terminated fiber cable, simplex/duplex cable, LSZH cables.

- Custom Fiber Optic Cable: Flex cable, FTTR cable, tactical cable, FTTA cable, pushable fiber cable, MPO cable, invisible cable.

- MTP/MPO Cable: High-density trunk cables, breakout cables, patch cords, adapters, patch panels.

- Data Center Cable: SFP modules, AOC cable, DAC cable, cable management systems, cassettes, patch panels.

- Fiber Patch Cords: Armored, SC, LC, ST, FC, ruggedized patch leads, single mode, multimode.

- Fiber Optic Accessories & Connectivity: Tools, connectors, adapters, reels, splicing and distribution enclosures.

I have worked closely with our R&D teams to ensure that custom requests are handled with care. I have visited many client sites. Some are in North America, while others are in Africa or the Middle East. We understand the climatic and logistical challenges these regions face.

Typical Steps When Working with AIMIFIBER on Custom Orders

| Step | Description | My Personal Tips |

|---|---|---|

| Requirement | Collect details (fiber count, mode, length, connector type, environment) | Provide as much detail as possible. |

| Engineering | Our team suggests materials, jacket type, and connector brand. | Share usage scenarios and environment conditions. |

| Sampling | We produce a sample or small run for testing. | Request performance test data and schedule a pilot test if needed. |

| Production | We finalize production. We ensure QC. We provide test reports. | Check the timeline, especially for big volumes. |

| Shipping & After-Sales | We pack, label, and arrange shipping. We handle after-sales inquiries. | Communicate shipping instructions early, discuss incoterms. |

I have seen how crucial these steps are, especially for new clients who need reassurance. We deliver test reports for insertion and return loss. We can also handle special packaging requests. Some clients want branding on each cable or box. Others need barcodes for internal logistics.

My Personal Anecdote

I often think about a project for a major data center client in Mexico. They wanted a large quantity of LC-LC patch cords in custom lengths, plus MTP trunk cables with unusual color coding. They had just won a yearly tender from a local telecom operator. They needed everything quickly. Our factory mobilized two production lines. We worked overtime for two weeks. We managed to ship on schedule. The client was so happy that they referred us to another local ISP. Moments like these remind me why a capable, flexible supplier matters.

Addressing Data Center and FTTA Challenges

Many of my readers manage data centers or plan FTTA rollouts. They face unique challenges:

- High Density in Data Centers: Cables must fit into limited space. Installation is time-consuming if you have to manually splice on-site. Pre-terminated cables help.

- Environmental Factors in FTTA: The cables are outdoors. They face wind, rain, UV exposure, and temperature swings. I have seen cell tower operators struggle with repeated connector replacements due to harsh weather.

- Customization Needs: No two installations are the same. Some want hybrid cables that carry fiber and power. Others want different fiber modes or special fire-retardant jackets.

- Cost vs. Quality: Price is always a consideration. But quality failures can cost more in the long run.

My Table of Key Considerations in Data Centers vs. FTTA

| Factor | Data Center | FTTA |

|---|---|---|

| Space Constraints | High-density demands, small cable diameter recommended | Less dense, but cable runs can be long and exposed |

| Connector Choices | Often MTP/MPO or LC for high-density | Outdoor-rated connectors like ODVA, FullAXS |

| Environmental Risks | Typically climate-controlled environment | Harsh weather, UV, mechanical stress |

| Fiber Mode | OM3/OM4 for short-range, Singlemode for longer runs | Singlemode is most common for tower connections |

| Maintenance | Cleanliness crucial for connectors | Weatherproofing and maintenance intervals |

I tell my customers to weigh each factor when selecting a supplier. A well-chosen custom cable solution can save headaches. If you only consider price, you might end up with frequent replacements.

Real-World Challenges and Lessons Learned

I have faced the reality that no project is the same. Some lessons I have learned:

- Lack of Clear Specs: Many new customers only have a vague idea of what they need. It is best to clarify fiber mode, connector type, length, environment, and the required pulling tension early.

- Shipping and Tariffs: Some countries have high import duties. I once had a client in Brazil who was surprised by the import tax. They had to revise the project budget. I now advise all clients to check local regulations.

- Documentation: High-quality suppliers provide insertion loss, return loss, and reflectance test reports. They also label cables. This labeling is very important when you have hundreds of cables.

- Backup Plans: Delays sometimes happen. My advice is to keep a small stock of spares.

Conclusion

Choosing the right supplier for custom fiber optic cables involves many considerations: range of products, industry-specific solutions, and customization options. In my experience, Infinite Cables, OFS Optics,Thorlabs,Opticonx, American Wire Group, and Cability, Inc. stand out. They deliver high-quality, tailored solutions that meet diverse requirements in data centers, FTTA, and many other telecom applications. By knowing what each supplier offers, telecom engineers and product managers can make informed decisions. This leads to more reliable connectivity and better project outcomes. When you need an even broader range of solutions, or when you want a partner that focuses on flexible customization and global delivery, you can also consider working with my team at AIMIFIBER. I have watched our manufacturing lines expand to handle new fiber types, new connector solutions, and new packaging requests. I know that every project is unique. I look forward to seeing more successful deployments in our industry.

A link offering insights into the specialty fiber optic solutions provided by OFS Optics, focusing on their industry applications. ↩

This link elaborates on Thorlabs' offerings, specifically their custom fiber optic solutions and their fast delivery services. ↩

Information on Opticonx's high-quality manufacturing processes and solutions tailored for data centers. ↩

Insights into the types of custom solutions offered by American Wire Group in fiber optics and why they are considered reliable. ↩

This link explains Cability, Inc.’s versatility in providing tailored fiber optic solutions. ↩

This link explains various types of fiber optic assemblies, their uses, and benefits in telecom projects. ↩

A link describing MTP/MPO connectors, their uses, and how they facilitate multifiber connections. ↩

This link provides understanding about polarization-maintaining fibers and their applications in preventing signal degradation. ↩