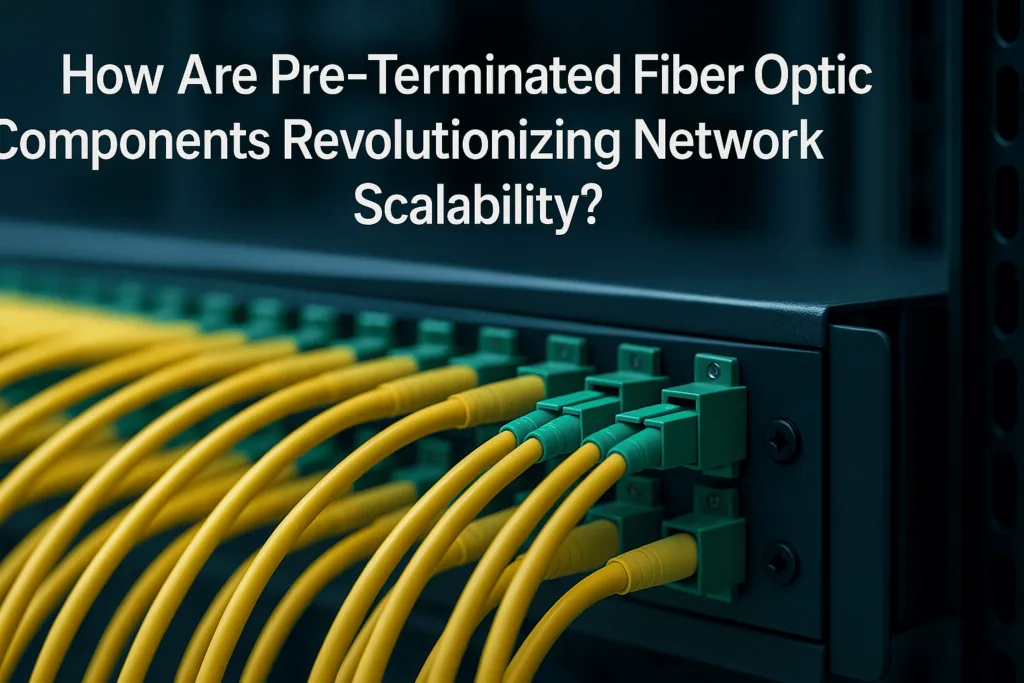

Network deployment can be slow and complex. Delays and high costs often stall progress. But, pre-terminated fiber optic components offer a faster, more efficient way to scale your network infrastructure.

Pre-terminated fiber components drastically speed up installation, reduce labor costs, and improve network reliability, making them key for rapidly expanding modern communication networks.

I’ve seen firsthand in my 14 years in this industry how crucial efficient deployment is. When I was negotiating a large FTTH project in Brazil, the ability to deploy quickly was a major factor. This is where pre-terminated solutions truly shine, changing how we approach network growth.

What is the Core Value of Pre-terminated Components in Today's Networks?

The demand for bandwidth is always growing. So, understanding the value of technologies like pre-terminated components is really important for everyone in the fiber optic industry, from project managers to installers.

Pre-terminated components deliver significant value by accelerating deployment times, supporting the intense demands of 5G/6G, and offering better energy efficiency than traditional copper systems.

Let's explore this a bit more. The industry landscape and technological advancements show why these components are so vital.

Industry Background and Market Momentum

The fiber optics market is experiencing significant growth.

- Market Growth: Take the "last-mile" fiber market, for instance. It's projected to expand from $5.62 billion in 2024 to $6.15 billion in 2025. This is a compound annual growth rate (CAGR) of 9.85%. This rapid growth highlights the urgent need for efficient deployment solutions. At AIMIFIBER, we see this demand reflected in orders for products like our FTTH Drop Cables and MPO/MTP Cable assemblies. (See more in the Last-Mile Fiber Optic Market Growth Report)

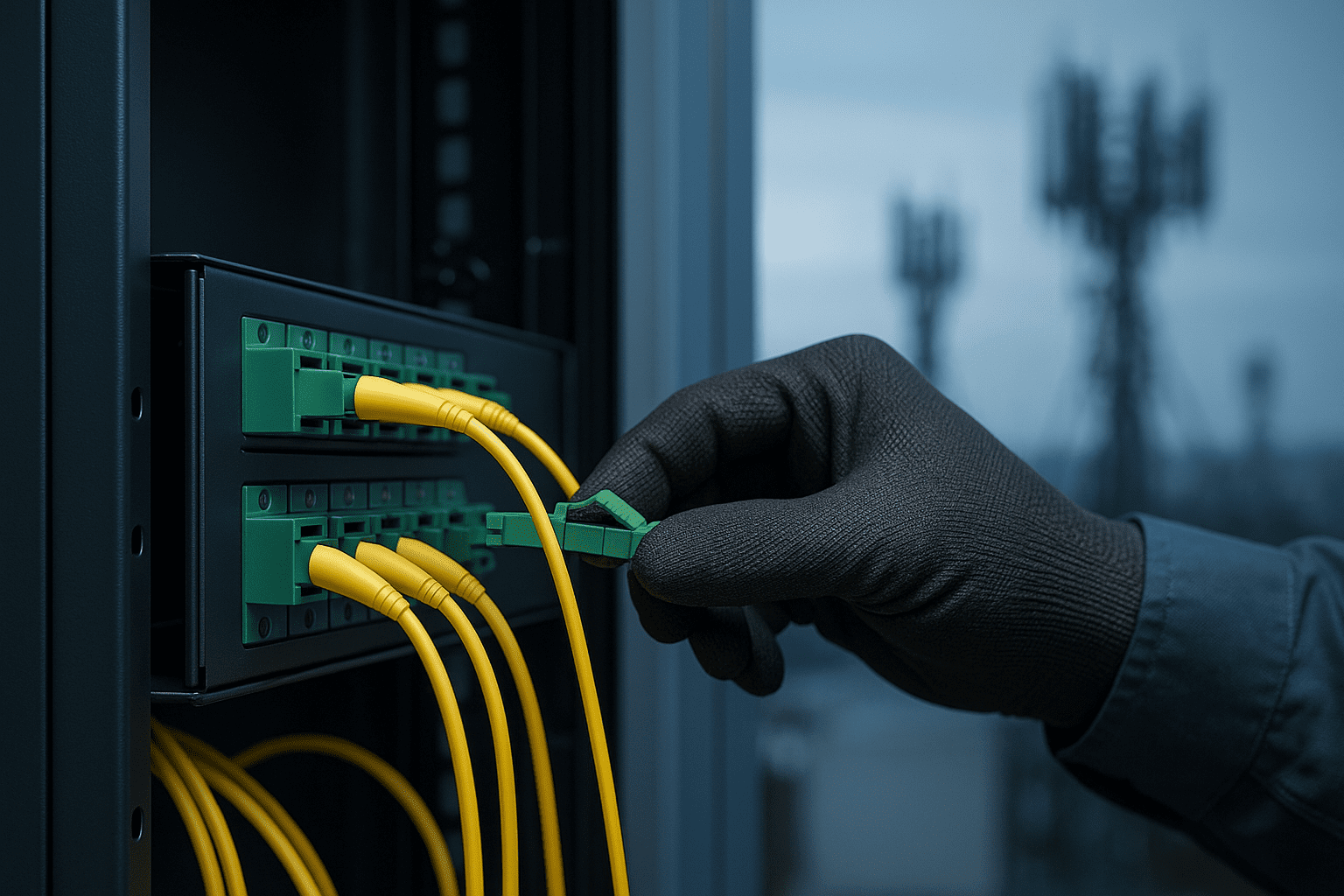

- Technology-Driven Demand: New technologies like 5G and upcoming 6G require high-density network coverage. Distributed network architectures also add to this demand. Pre-terminated components are strategically important here. They allow for the quick deployment needed. I remember discussing this with Bayan, a project manager from the US, who emphasized how critical rapid, reliable connections are for his data center and FTTA projects.

The Turning Point: Standardized Components

Standardization is a game-changer.

- From Custom to Modular: Traditionally, fiber optic installations involved a lot of custom, on-site termination work. This was time-consuming and required skilled technicians. Now, with pre-terminated components, we're moving to a fully modular approach. This means faster deployment and less room for error. Our Pre Terminated Fiber Cables are a perfect example of this shift. (Learn more about Types of Fiber Cables and Connectors)

- Energy Consumption Optimization: It's also worth noting the environmental benefits. Fiber optic cables are much more energy-efficient than copper cables. Studies show that switching to fiber can reduce energy consumption by up to 54%. Standardized components contribute to this by simplifying network design and maintenance, which in turn helps lower overall operational costs.

How Do Standardized Components Reshape Traditional Network Topology Thinking?

Traditional network setups often faced limitations. But, with standardized components like those we offer at AIMIFIBER, we're seeing a fundamental shift in how networks are designed and expanded.

Standardized components allow for modular, plug-and-play network expansion, moving away from complex, error-prone manual terminations and enabling more flexible, scalable network designs.

I've seen this transformation in many projects. Early in my career, deploying a network involved many intricate steps on-site. Now, projects can move much faster.

Limitations of Traditional Topology

Traditional network topology had its challenges.

- Deployment Complexity: Manual termination processes were quite involved. Technicians had to cut, strip, cleave, splice, and polish fibers on-site. This required highly skilled personnel and a lot of time. I recall visiting sites where this meticulous work, while essential, was a bottleneck.

- Potential for Faults: Non-standardized termination interfaces could lead to signal loss issues, such as high return loss. This directly impacted network reliability and performance. (Read more about Key Specifications of Single-Mode Fiber Optic Cables)

Architectural Innovation Driven by Standardized Components

Standardized components bring a new level of innovation.

- Component-Level Standardization: Different types of pre-terminated components offer specific advantages.

| Component Type | Standardization Advantage | Common Use Case |

|---|---|---|

| MPO/MTP Pre-terminated | High-density, multi-port connections for rapid expansion | Data Centers, Enterprise Networks |

| Fiber Optic Pigtails | Factory-polished ends for reliable connections | Splicing into existing networks |

| Pre-connectorized Cables | Ready-to-deploy cables (e.g., FTTH Drop Cable with SC/APC) | FTTH, FTTB |

- Shift in Network Design Paradigm: We're moving from optimizing single links to a more holistic, modular approach. Pre-terminated components, like our MPO/MTP Trunk Cables and MPO/MTP Cassettes, work alongside equipment like fiber amplifiers (EDFA/SOA) to build robust, distributed architectures. This is something Fernando from Amper Group in Spain values, as his projects for Telefonica demand high quality and future-proof designs.

Focusing on Design Efficiency and Maintainability

Efficiency and maintenance are key benefits.

- Deployment Efficiency Boost: Traditional field termination is labor-intensive. Pre-terminated components offer a mechanical, quick plug-and-play solution. This can lead to significant time savings. Some industry observations suggest productivity increases of around 21% or more in deployment speed. (More on Installation and Maintenance of Fiber Optic Cable Systems)

- Improved Maintainability: Standardization simplifies troubleshooting and replacement. If a component fails, it can be quickly swapped out with a new pre-terminated unit. This can reduce network downtime. While specific data varies, it's widely accepted that standardized, factory-tested components lead to lower network fault rates.

Final thoughts

Pre-terminated components are more than just an incremental improvement; they represent a fundamental shift in how we design, build, and manage robust, scalable fiber optic networks for the future.